Flooring can completely transform a room—from making it feel cozy and inviting, to ensuring it stays practical for everyday life. Among all the newer flooring options out there, WPC (Wood Plastic Composite) stands out for its mix of comfort, resilience, and easy maintenance. It’s basically a step up from standard vinyl, offering a bit of cushion and warmth without compromising durability. But how exactly does it work, and why are so many people curious about it?

WPC flooring uses a wood-plastic composite core, combining wood pulp, PVC, and foaming agents for extra warmth and comfort underfoot. It’s often thicker and quieter than standard vinyl, while still being water-resistant and simple to maintain. This blend of performance and cushioning makes WPC ideal for families, busy kitchens, and places where softer floors are a plus.

Picture stepping onto a floor that looks and feels just a bit more luxurious—like real hardwood in appearance, but without the worries about moisture, dents, or high maintenance. That’s what WPC promises: a modern solution for people who want both style and practicality. Let’s break down how it’s made, what sets it apart from other vinyl floors, and how long you can expect it to last.

I. Introduction: What Is WPC Flooring?

WPC (Wood Plastic Composite) flooring is a type of luxury vinyl featuring a composite core of wood pulp, plastics, and foam. This core adds softness and warmth, making WPC more comfortable and insulating than standard vinyl.

Understanding the WPC Foundation

- Core Composition

- Wood-Plastic Blend: Typically contains a mix of wood flour or pulp, PVC, and foaming agents. This creates a thicker, foam-like middle that feels slightly “bouncier” than typical vinyl or rigid-core SPC floors.

- Why It Matters: The foam composition traps air pockets, contributing to better thermal insulation and a softer feel underfoot. Great for rooms where you’re on your feet a lot, like the kitchen.

- Layers of WPC

- Wear Layer: A transparent top coating that resists scratches, spills, and day-to-day foot traffic.

- Printed Design Layer: Provides the look—whether you prefer rustic oak or sleek marble patterns. High-definition printing can mimic natural materials remarkably well.

- WPC Core: The thick, wood-plastic composite center that adds warmth and cushioning.

- Underlayment (Sometimes): Some WPC floors have an attached pad for extra sound absorption and comfort.

- Market Perspective

- Evolution from Vinyl: Vinyl has come a long way from thin sheets. WPC is part of a new generation of “engineered vinyl,” offering more insulation and stability.

- Popularity: Busy households and commercial spaces alike appreciate the combination of easy upkeep, water resistance, and foot-friendly feel.

- Example Scenario

- Family Kitchen: If you’re constantly cooking or hosting, WPC’s padded surface can ease leg fatigue and handle the inevitable dropped dishes without denting.

- A Friendly Approach

- DIY Potential: Most WPC planks come with click-lock edges, so homeowners can install them with minimal fuss.

- Aesthetic Variety: No more limited vinyl looks—WPC can impersonate everything from beachy white oak to travertine tile.

II. How Does WPC Flooring Differ from Other Types of Vinyl and SPC?

WPC floors have a foam-like wood-plastic core, offering more warmth and cushioning compared to regular vinyl. SPC (Stone Plastic Composite) is denser and harder, while standard vinyl lacks the thicker core that provides WPC’s extra comfort.

Key Distinctions

- Core Materials

- WPC: Wood pulp, plastics, foaming agents—lighter and more flexible.

- SPC: Stone powder and plastic for maximum rigidity and dent resistance.

- Standard Vinyl: Pure PVC layers without the foamy center, generally thinner and less insulating.

- Underfoot Feel

- WPC: Softer, with a slight “bounce” due to its wood-plastic composite.

- SPC: Very solid underfoot, which some people find too firm.

- Basic Vinyl: Flexible and can conform to subfloor imperfections; can feel harder if laid directly on concrete.

- Performance Factors

- Temperature Sensitivity: WPC’s foam core helps retain warmth, so your feet might not freeze on chilly mornings.

- Dent Resistance: SPC typically outperforms WPC if heavy furniture or high-impact loads are common.

- Cost and Availability

- WPC: Usually on the higher-end side of vinyl pricing, reflecting its foam core and comfort factor.

- SPC: Also premium, but might be slightly cheaper or about the same, depending on brand and thickness.

- Standard Vinyl: Ranges widely—some very affordable roll vinyl or more expensive luxury planks.

- Use Cases

- WPC: Ideal for cozy living rooms, kitchens, bedrooms—where you appreciate a softer surface.

- SPC: Perfect for high-traffic commercial settings or anywhere dents are a major concern.

- Regular Vinyl: Good for budget upgrades, rental units, or simpler renovations.

| Feature | WPC Flooring | SPC Flooring | Standard Vinyl Flooring |

|---|---|---|---|

| Core Materials | Wood pulp, plastics, foaming agents—lighter and more flexible. | Stone powder and plastic—rigid, dense, and highly durable. | Pure PVC layers—thinner, lacks additional core cushioning. |

| Underfoot Feel | Softer, with a slight “bounce” due to its foamed core. | Very solid underfoot, may feel too firm for some users. | Flexible but can feel harder if installed directly on concrete. |

| Temperature Sensitivity | Retains warmth well, making it more comfortable in colder environments. | Less insulating; feels cooler in cold conditions. | Can feel cold unless installed with an insulating underlayer. |

| Dent Resistance | Moderate—softer core may dent more easily under heavy loads. | High—rigid core resists dents from furniture or impacts. | Lower—may dent easily, especially in thinner varieties. |

| Cost & Availability | Higher-end pricing due to its comfort-enhancing core. | Also premium but may be slightly less expensive than WPC. | Wide price range—affordable sheet vinyl to high-end luxury planks. |

| Use Cases | Best for residential areas like living rooms, kitchens, and bedrooms needing comfort. | Ideal for high-traffic commercial spaces or homes where durability is key. | Suitable for budget-friendly upgrades, rental units, or temporary solutions. |

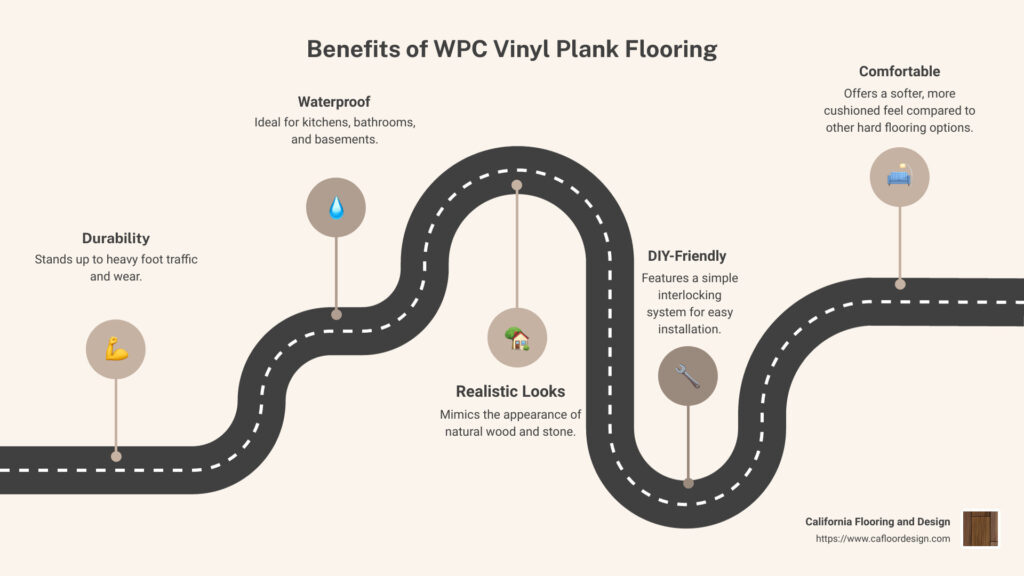

III. Which Benefits Make WPC Flooring Stand Out?

WPC floors excel in warmth, cushioning, and sound absorption, offering a comfy underfoot experience while maintaining water resistance and easy installation.

Why Pick WPC?

- Enhanced Comfort

- Foam-Like Core: If you hate standing on cold, rigid surfaces, WPC’s core is a game-changer, particularly for kitchens or bathrooms.

- All-Day Standing: This slight cushion helps reduce fatigue—great if you cook a lot or stand at a home workstation.

- Noise Reduction

- Multi-Story Homes: WPC’s thicker core muffles footstep sounds, beneficial in upstairs bedrooms or busy hallways.

- Commercial Offices: Reduces echo in open spaces, creating a more pleasant work environment.

- Thermal Insulation

- Heat Retention: WPC doesn’t feel as cool to the touch, making it friendlier for bare feet, especially in colder climates.

- Energy Saving: While not a huge difference, every bit of insulation can help maintain indoor temperatures.

- Design Flexibility

- Countless Patterns: From rustic farmhouse planks to modern stone-like tiles, WPC can match any decor style.

- Realistic Textures: Embossed surfaces add a tactile feel reminiscent of real wood grain or chiseled stone.

- User-Friendly Installation

- Click-Lock Systems: Often straightforward for DIYers, with planks snapping in place.

- Subfloor Tolerance: WPC can bridge minor subfloor imperfections better than thinner vinyl.

| Feature | WPC Flooring Benefits |

|---|---|

| Enhanced Comfort | Foam-like core provides cushioning, reducing foot fatigue—ideal for kitchens and home workstations. |

| Noise Reduction | Thicker core absorbs sound, making it great for multi-story homes and commercial offices. |

| Thermal Insulation | Retains warmth, making floors feel more comfortable in colder climates and helping with minor energy savings. |

| Design Flexibility | Offers a wide range of patterns and textures, mimicking real wood, stone, and other materials. |

| User-Friendly Installation | Click-lock systems make installation easier for DIYers, and WPC can tolerate slight subfloor imperfections better than standard vinyl. |

IV. Is WPC Flooring Truly Waterproof?

Yes. WPC’s plastic-encased core resists water damage and prevents swelling, but standing water should still be addressed quickly to avoid subfloor or mold problems.

Water-Resistance Details

- Core Encapsulation

- Wood Meets Plastic: The wood pulp is locked in a PVC matrix, blocking direct moisture penetration.

- Protective Layers: A tough wear layer and sealed edges further defend against spills seeping in.

- Dealing with Spills

- Everyday Mishaps: Whether it’s cooking splashes or pet accidents, WPC can handle quick wipe-ups without warping.

- Extended Exposure: No floor is invincible—floods or lengthy pooling can cause subfloor damage, so act fast in emergencies.

- Comparison with Other Floors

- Laminate: Often swells or peels if exposed to water.

- Hardwood: Can warp or rot if not dried promptly.

- SPC: Similarly waterproof but lacks WPC’s foam-like comfort.

- Best Practices

- Seal Edges: If installing in a high-moisture area (like bathrooms), seal transitions around tubs or toilets for extra protection.

- Regular Cleaning: Simple sweeping and a damp mop are enough—don’t soak the floor or let water stand.

- Room-by-Room Reality

- Bathrooms: WPC is a top choice, but consider caulking along baseboards to block splashes.

- Kitchens: Survives spilled soup or dishwasher leaks better than hardwood.

- Basements: Great for damp-prone spaces, so long as you address major water intrusion issues.

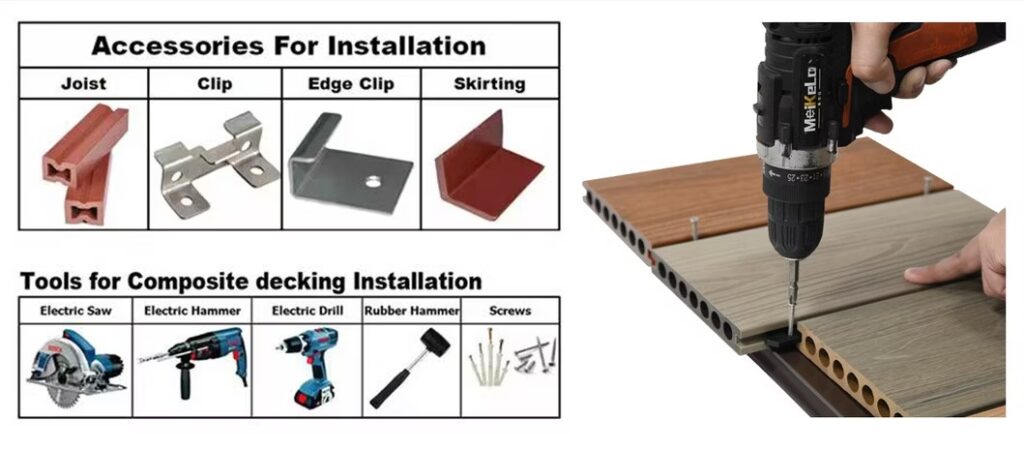

V. How Do You Install WPC Flooring?

Most WPC planks click-lock for a floating installation. A clean, level subfloor, proper acclimation, and a small expansion gap ensure a stable, long-lasting floor—perfect for both DIYers and pros.

Step-by-Step Approach

- Subfloor Prep

- Cleaning: Remove debris or leftover adhesives from previous flooring.

- Leveling: Small dips can be bridged by WPC, but major unevenness needs patching or self-leveling compound.

- Acclimation

- 24–48 Hours: Keep the unopened boxes in the room to match temperature and humidity.

- Temperature Range: WPC typically likes an environment of around 65–85°F (18–29°C).

- Floating Click-Lock

- Joining Planks: Align the tongue and groove, then gently tap into place with a tapping block.

- Spacers: Maintain about a 1/4-inch gap at walls or permanent fixtures for expansion.

- Glue-Down Method

- When Used: More common in large commercial areas or if you want extra stability.

- Adhesives: Follow manufacturer guidelines on trowel size, spread rate, and open time.

- Finishing Touches

- Trim & Baseboards: Covers expansion gaps for a clean, polished perimeter.

- Transitions: Use transition strips where WPC meets tile, carpet, or other flooring.

Sample Installation Materials Table (Copy & Paste)

| Material/Tool | Purpose | Typical Use Frequency |

|---|---|---|

| Utility Knife/Jigsaw | Cutting WPC planks to fit corners & edges | Regular cutting tasks |

| Tapping Block & Spacers | Ensuring tight seams & expansion gaps | Every row of planks |

| Self-Leveling Compound | Leveling subfloor dips >1/8 inch | As needed |

| Underlayment (optional) | Additional cushioning & sound insulation | Based on WPC brand |

| Measuring Tape & Pencil | Accurate measurements & marking cut lines | Constantly |

With a bit of patience and the right tools, installing WPC can often be a weekend project for a standard-size room.

VI. What Is the Life Expectancy of WPC Flooring?

Quality WPC floors typically last 10–20 years, depending on wear layer thickness, product quality, foot traffic, and maintenance.

WPC Longevity Factors

- Wear Layer Thickness

- 8 mil vs. 20 mil: Thicker wear layers stand up to repeated scuffs, while thinner ones may show wear faster in busy homes.

- Heavier Traffic: Kids, pets, or rolling furniture can test the floor’s durability daily.

- Material Quality

- High-Grade Cores: Premium WPC often includes better bonding agents, limiting break down over time.

- Brand Reliability: Well-known manufacturers typically produce more consistent, tested products.

- Installation & Subfloor

- Proper Prep: A level, clean subfloor prevents stress on plank joints.

- Correct Expansion Gaps: Reduces the risk of warping or buckling that might shorten the floor’s lifespan.

- Daily Maintenance

- Sweep & Mop: Removing abrasive grit or spills helps keep the wear layer intact.

- Furniture Pads: Placing felt pads under heavy furniture is a small step that significantly reduces dents.

- Commercial vs. Residential

- Residential: 15–20 years is common for well-installed, high-quality WPC.

- Commercial: Heavy foot traffic or rolling carts may drop that range to 10–15 years.

- Warranty Insights

- 15–20 Years: Many WPC warranties promise coverage over two decades for residential use.

- Fine Print: Misuse, extreme temperatures, or ignoring installation guidelines may void the warranty.

| Factor | Impact on WPC Flooring Longevity |

|---|---|

| Wear Layer Thickness | Thicker wear layers (e.g., 20 mil) resist scuffs and wear better than thinner options (e.g., 8 mil). |

| Material Quality | High-grade cores with strong bonding agents enhance durability and limit breakdown over time. |

| Installation & Subfloor | Proper subfloor preparation and correct expansion gaps prevent warping, buckling, and premature damage. |

| Daily Maintenance | Regular sweeping and mopping protect the wear layer; furniture pads prevent dents and scratches. |

| Residential vs. Commercial Use | Residential lifespan is typically 15–20 years; heavy commercial use may shorten it to 10–15 years. |

| Warranty Coverage | Many warranties cover 15–20 years for residential use, but improper installation or extreme conditions may void coverage. |

In general, WPC performs admirably for households or light commercial settings, bridging the gap between shorter-lived low-end vinyl and high-maintenance hardwood.

VII. Are There Any Drawbacks or Limitations to WPC Flooring?

WPC can be pricier than basic vinyl, compress under very heavy loads, and still needs proper subfloor prep. It’s more robust than laminate but isn’t wholly immune to extreme temperature swings or long-term moisture issues.

Potential Challenges

- Cost Considerations

- Higher Initial Investment: WPC often carries a bigger price tag than standard vinyl due to its foam core.

- Is It Worth It?: Many find the added comfort, warmth, and longevity justify the extra spend.

- Heavy Furniture and Indentations

- Point Loads: A piano leg or massive bookshelf might leave slight impressions over time without protective pads.

- Comparison with SPC: If dent-resistance is top priority, SPC’s stone core usually wins.

- Subfloor Requirements

- Minor Tolerance: WPC hides small bumps better than sheet vinyl, but large dips or cracks still need fixing.

- Moisture Barrier: Even though WPC is waterproof, a damp subfloor can lead to mold or adhesive issues.

- Thermal & UV Sensitivity

- Excessive Heat: Installing WPC in a sunroom with intense direct heat can cause expansion or slight discoloration.

- Freezing Climates: Vacant holiday homes that go unheated in winter might present challenges if the floor is subjected to extreme cold.

- Brand Variability

- Inconsistent Quality: Cheap WPC might use lower-grade wood pulp or adhesives, reducing performance.

- Warranty Range: Some brands offer robust coverage, others don’t, reflecting their confidence in product integrity.

| Drawback | Potential Impact & Considerations |

|---|---|

| Cost Considerations | WPC is pricier than standard vinyl due to its foam core, but many find the added comfort and durability worth the investment. |

| Heavy Furniture & Indentations | Heavy point loads (e.g., pianos, bookshelves) may leave slight impressions over time unless protective pads are used. SPC flooring offers better dent resistance. |

| Subfloor Requirements | WPC hides minor imperfections but still requires leveling for larger dips or cracks. A moisture barrier may be necessary to prevent mold issues. |

| Thermal & UV Sensitivity | Prolonged exposure to extreme heat (e.g., sunrooms) may cause expansion or discoloration. In freezing conditions, unheated spaces might affect performance. |

| Brand Variability | Lower-quality WPC products may use inferior wood pulp or adhesives, affecting durability. Warranty coverage varies widely by brand. |

Despite these limitations, WPC remains a top choice for many, especially if comfort and a warmer underfoot feel are non-negotiables.

VIII. Conclusion: Is WPC Flooring Right for Your Needs?

WPC (Wood Plastic Composite) flooring stands out in the vinyl family for its cozy, insulated feel and water-resistant build, offering households a delightful mix of style and functionality. Unlike traditional vinyl, its wood-plastic core lends a softer step—something you’ll appreciate if you’re on your feet all day or simply crave a more welcoming surface underfoot. Add in the fact that it’s easy to maintain, offers impressive design variety, and can handle spills without drama, and it’s no surprise WPC is becoming a go-to for modern renovations.

Still, it’s not a one-size-fits-all solution. If your budget is tight or you’re dealing with extremely heavy loads, you might compare WPC with standard vinyl or even SPC (Stone Plastic Composite). And while WPC floors are pretty forgiving, a level subfloor and proper installation go a long way in ensuring they last for 10, 15, or even 20 years.

If you’re intrigued by WPC flooring and want a custom solution tailored to your space—whether it’s a busy kitchen, a cozy living room, or a commercial showroom—reach out to Kinwin for a personalized quote. Our team specializes in high-quality, eco-conscious flooring solutions that strike the perfect balance between durability, comfort, and style. Let us help you pick the ideal WPC floor so you can enjoy a warm, beautiful, and hassle-free surface for years to come!