Premium WPC Fencing & Pergolas: Eco-Friendly, Durable, Stylish

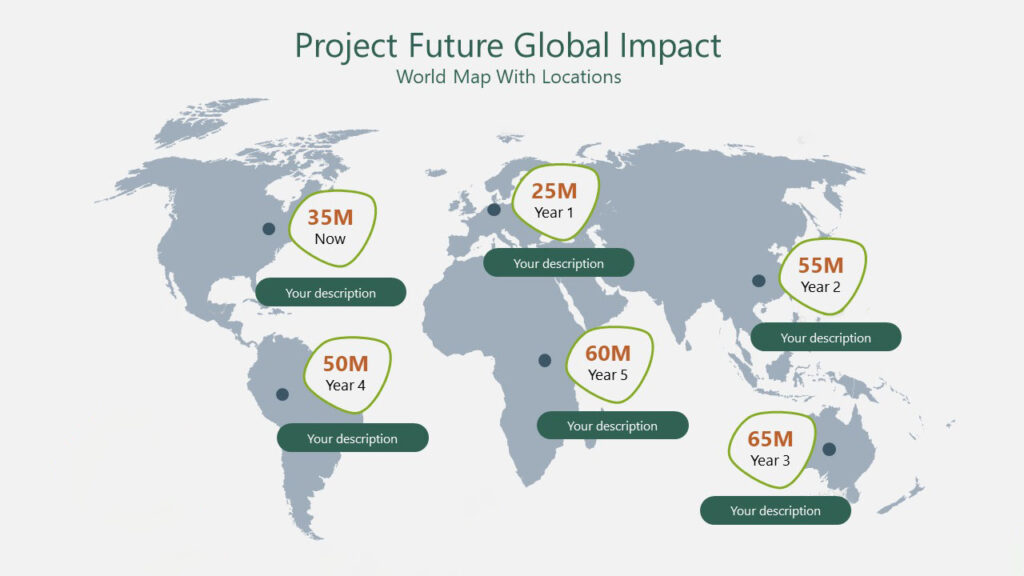

18 Years Expertise, 1000 ton Annual Capacity, Reliable Supply for Global Projects

Elevate your outdoor space with our WPC (Wood Plastic Composite) fencing and pergolas – sustainable, low-maintenance solutions that blend the beauty of wood with the durability of plastic. Perfect for gardens, villas, parks, and commercial spaces, our products offer unmatched weather resistance and aesthetic appeal.

Your Trusted WPC Manufacturer

With 18 years of expertise, we are a leading manufacturer of WPC fencing and pergolas, supplying over 90 countries. Our advanced facilities, rigorous quality control, and eco-friendly production ensure durable, high-performance products tailored for residential, commercial, and public projects.

Large-Scale Production Capacity

– 15,000㎡ modern plant with 28 fully automated extrusion lines

– Dual ISO 9001/14001 certified, implementing 6S lean management

– Closed-loop control from raw materials to shipping

Industry-Leading Machinery

– 2nd-gen co-extrusion technology extends product lifespan by 50%

– Intelligent temperature control (±1℃) guarantees material consistency

Factory Introduction - Your Reliable WPC Manufacturing Partner

Company Background

Over 18 years of development, we have grown from a local workshop to an international WPC specialist. Our 1,000 ton production base in Guangdong province, foshan city houses state-of-the-art facilities and 200+ skilled workers. The strategic location (2hrs to shenzhen Port) ensures efficient global logistics.

Production Capabilities

With 28 automated production lines, our annual capacity reaches 1000ton – enough to cover 2 soccer fields. German-made equipment and lean manufacturing ensure defect rates below 0.3%. Our patented 2nd-gen co-extrusion technology extends product lifespan by 50% compared to conventional WPC.

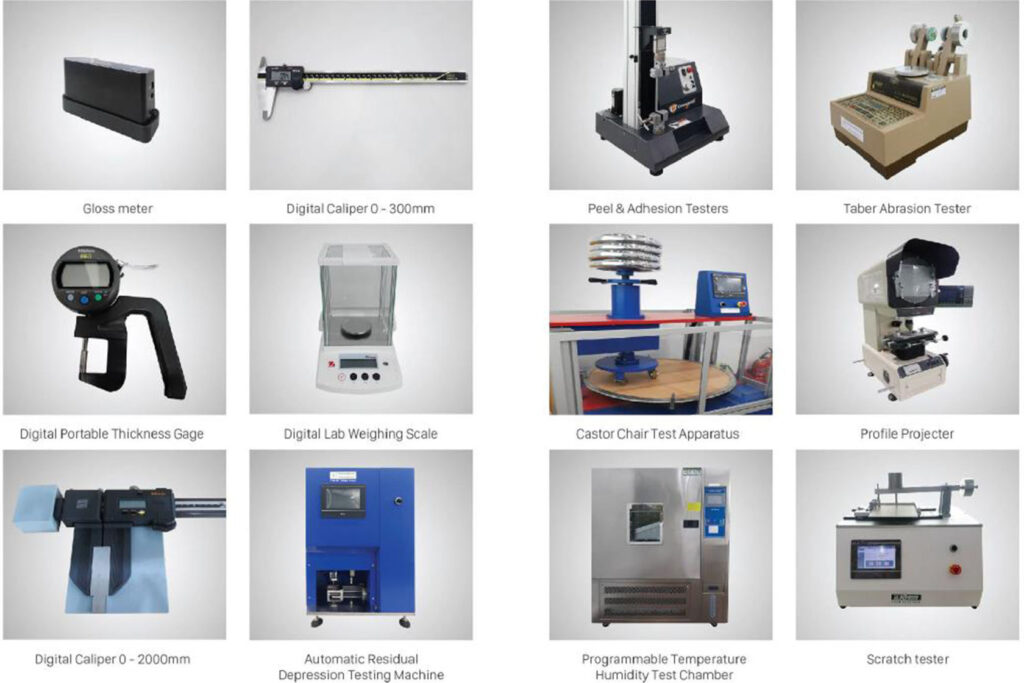

Quality Certifications

Quality is our core competency. We hold ISO 9001, ISO 14001, CE, FloorScore and FSC certifications. Our lab conducts 36 rigorous tests including 72hr boiling and 5,000 compression cycles using QUV weatherometers and universal testing machines.

Sustainable Development

We prioritize sustainability: 30% recycled materials, 95% waste recycling rate, 30% solar-powered. All products meet EU REACH standards with 0.01mg/m³ formaldehyde (80% lower than E0 standard). These efforts earned us “China Green Building Material” title for 5 consecutive years.

R&D Innovation

We invest 5% of revenue in R&D, holding 23 patents. Our 15-material-science PhD team collaborates with Guangdong University. The newly developed “nano-enhanced WPC” increases flexural strength by 40%, now used in premium projects.

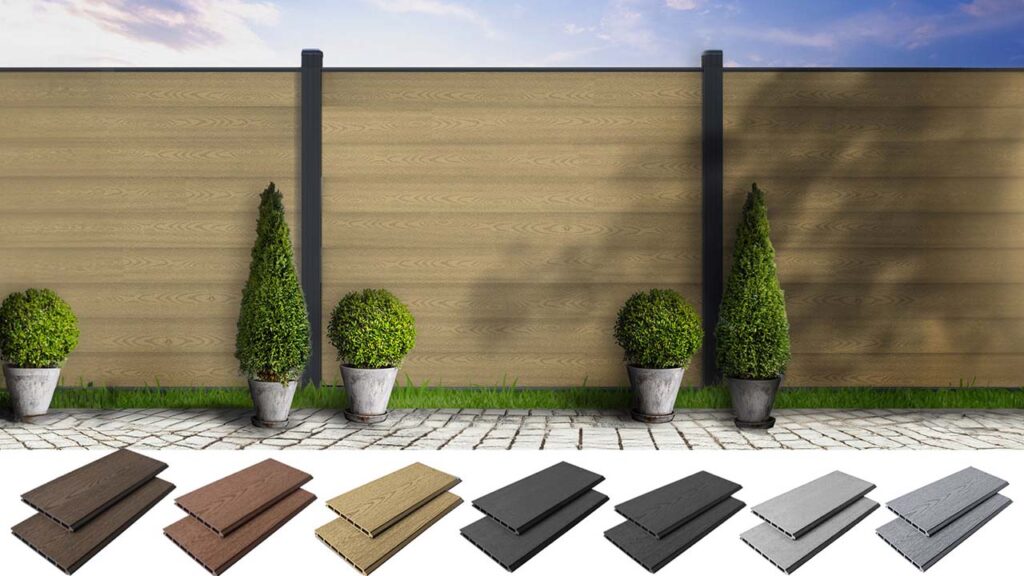

EcoGuard Privacy WPC Fence

Fully enclosed panels for maximum privacy and security, ideal for residential gardens and villas, with UV-resistant, anti-corrosion properties.

FlexiTrellis WPC Fence

Semi-open trellis design for ventilation and aesthetics, perfect for patios and public parks, resisting moisture and insects.

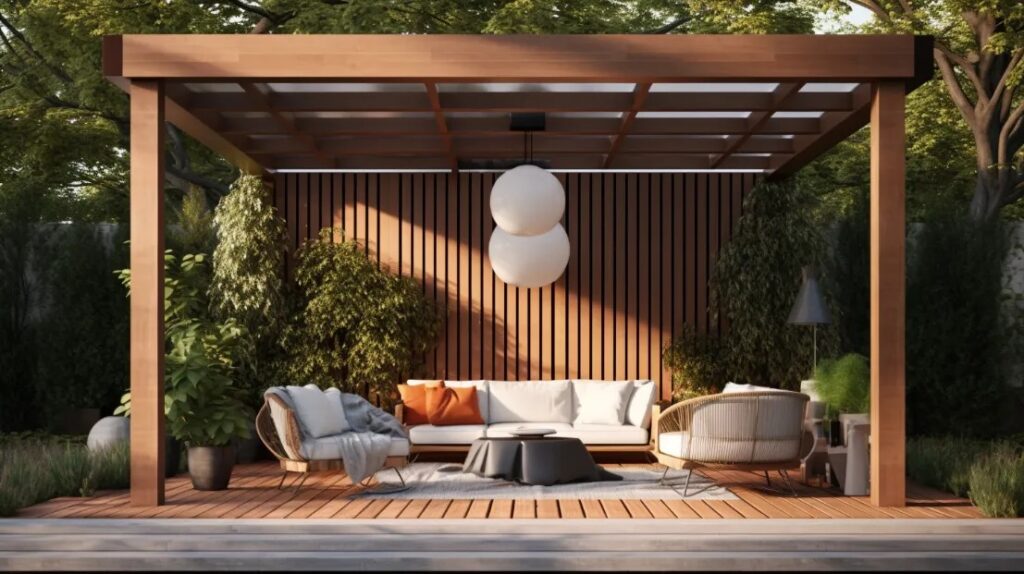

Classic WPC Pergola

Elegant open-roof structure for shade and plant support, designed for gardens and resorts, with weatherproof and low-maintenance features.

ODM/OEM Services for Your WPC Needs

Why Choose Our ODM/OEM Services

Want a partner you can trust for WPC products? Our ODM/OEM services give you flexibility and reliability. Whether you need custom OEM production or fast ODM solutions, we’ve got you covered. We work with material wholesalers, construction firms, and developers to deliver top-quality WPC decking, fencing, furniture, and more. Our team offers design help, quality assurance, and custom packaging to fit your needs. You get durable, sustainable products that stand out in the market. Plus, our efficient process ensures on-time delivery for your projects or sales. Choose us for a smooth, professional experience—let’s grow your business together!

Why Choose Us?

Your Trusted WPC Partner with 18 Years of Experience

Are you looking for high-quality WPC products that save costs, meet deadlines, and support your projects? With 18 years of experience, we deliver reliable solutions for wholesalers, builders, and developers worldwide. Here’s why we’re your best choice:

18 Years of Proven Experience

You need a supplier you can trust. With 18 years in the WPC industry, we’ve served over 50 countries and completed 1,000+ projects. Our expertise ensures your success.

Top-Quality Products You Can Rely On

Worried about durability? Our WPC products use premium materials and pass strict ISO 9001 and CE tests. They last up to 25 years with minimal maintenance.

Powerful Production for Your Big Orders

Need fast delivery for large orders? Our modern factories and 10+ production lines produce 30,000 tons yearly. We meet your deadlines every time.

Customization to Fit Your Needs

Want unique designs? We offer custom colors, sizes, and styles for your projects. Over 80% of our clients choose tailored solutions.

Competitive Prices, Maximum Value

Looking to save costs? Our optimized process cuts prices by up to 15% compared to competitors, while keeping top quality. You get more for your money.

Expert Support Every Step of the Way

Need help with your project? Our team offers 24/7 support, from design advice to after-sales service. 95% of our clients rate us 5 stars for support.

Eco-Friendly Solutions for a Better Future

Care about sustainability? We use 70% recycled materials and meet LEED standards. Build green with products that last and protect the planet.

Global Reach, Local Trust

Want a partner with a worldwide reputation? We export to 60+ countries and have 500+ happy clients. You’re in safe hands with us.

Your Success Starts Here

Ready to grow your business with the best WPC products? Contact us today for a free quote and see the difference 18 years of experience makes!

Production Process of WPC Products

Welcome to KINWIN! We are a WPC (Wood-Plastic Composite) manufacturer with 18 years of experience, dedicated to delivering high-quality products for the building materials industry. WPC is an eco-friendly, durable material used for outdoor decking, fencing, and cladding. Explore our production process to see how we ensure quality and add value to your projects.

Raw Material Preparation

We select sustainable wood fibers (like recycled wood), ground into fine powder, and use high-density polyethylene (HDPE) as the plastic base. Additives like coupling agents, stabilizers, and colorants are mixed in to ensure performance. Everything is blended evenly for the next step.

– Wood-to-plastic ratio: 60:40

– Wood fiber particle size: 20-60 mesh

– Mixing time: 5-10 minutes

Extrusion Molding

The mixed materials are fed into an extruder, shaped into profiles (like decking or cladding) using heat and molds. After cooling, the profiles stay strong and stable.

– Extrusion temperature: 180-220°C

– Extrusion speed: 2-5 meters/minute

– Cooling method: Water bath

3D Embossing (Hot Pressing)

Using hot pressing, we imprint realistic wood grain or custom patterns onto the WPC surface with heated molds and foils, boosting beauty and durability.

– Pressing temperature: 150-200°C

– Pressure: 2-5 MPa

– Embossing time: 30-60 seconds

Cutting

We use precise equipment to cut profiles to your required lengths, ensuring perfect accuracy.

– Cutting accuracy: ±1 mm

– Productivity: 100 pieces/hour

Quality Inspection

Every batch is rigorously tested for strength, water absorption, and appearance, meeting international standards.

– Pass rate: 99%

– Tests per batch: 10 times

Watch Our Factory Video

Conclusion

At KINWIN, we use advanced technology and strict processes to create top-quality WPC products. With 18 years of experience, we’re your trusted partner. Contact us today for more details or to place an order!

Combustion Test

– Your Problem: Worried about building materials in a fire? Fires can risk your projects and people.

– Our Solution: Our WPC products pass ASTM E84 combustion testing for safe fire performance.

– Your Benefits: Flame Spread Index below 25, Smoke Developed Index below 450, meeting Class A standards—safer projects.

– Next Step: Choose our WPC products for strong fire protection in your buildings!

Pressure Test

– Your Problem: Concerned materials can’t handle heavy loads? Poor materials may cause structural issues.

– Our Solution: Our WPC products pass ASTM D6108 pressure testing, showing excellent strength.

– Your Benefits: Compressive strength over 30 MPa—strong and durable for all construction needs.

– Next Step: Use our WPC products to build solid, reliable structures!

Boiling Test

– Your Problem: Worried about materials warping in humidity? It can affect building stability.

– Our Solution: Our WPC products pass ASTM D570 boiling tests for performance in wet conditions.

– Your Benefits: Water absorption below 2%, stays stable in humidity—great for outdoor use.

– Next Step: Pick our WPC products for worry-free results in wet environments!

Aging Test

– Your Problem: Want materials that last over time? Long exposure can cause aging.

– Our Solution: Our WPC products pass ASTM G155 aging tests, mimicking years outdoors.

– Your Benefits: After 500 hours (about 5 years outdoors), color change ΔE is less than 5—long-lasting quality.

– Next Step: Invest in our WPC products for lasting beauty and performance!

Conclusion

– Your Problem: Looking for reliable WPC products to make your projects succeed?

– Our Solution: Our QC process—with combustion, pressure, boiling, and aging tests—ensures safe, durable products.

– Your Benefits: Meets global standards, delivering reliable performance and safety for your projects.

– Next Step: Contact us now to learn more or order our WPC products!

Buying Guide

Here are some common questions and answers about LVT flooring to help you better understand our products and services.

1. Commonly Used WPC Boards for Fencing and Pergolas

– Fence Panels: 150x20mm, 160x20mm, 169x21mm; co-extruded or embossed for wood-like texture.

– Pergola Beams/Posts: 120x120mm, 200x200mm; solid or hollow profiles for structural strength.

– Composition: 60% wood fiber, 30% HDPE, 10% additives (UV stabilizers, anti-oxidants).

2. Classic Styles of WPC Fencing and Pergolas

WPC Fencing

Fully Enclosed

Privacy-focused, ideal for villas and pools.

Semi-Enclosed (Trellis)

Ventilation and aesthetics, suited for gardens and parks.

Open (Picket)

Decorative, perfect for pathways and public spaces.

WPC Pergolas

Open-Roof

Classic lattice for shade and climbing plants, used in gardens.

Half-Covered

Partial roofing for weather protection, ideal for resorts.

ully Covered

Enclosed for full shade, suited for commercial patios.

3. Commonly Used Installation Accessories

WPC Posts

95x95mm or 120x120mm for fencing; 200x200mm for pergolas.

Connectors

Stainless steel clips, screws, and brackets for secure assembly.

Base Plates

Galvanized steel for anchoring pergola posts to concrete.

WPC Caps

Decorative covers for posts, enhancing aesthetics and weather resistance.

4. Benefits of Using WPC for Fencing and Pergolas (Compared to Treated Wood)

WPC

– Durability: Resists rot, insects, and UV, lasting 15-25 years.

– Low Maintenance: No painting/staining, saving 30% upkeep costs.

– Eco-Friendly: 100% recyclable, using 60% recycled materials.

– Weather Resistance: Waterproof, no warping or cracking in -40°C to 60°C.

Treated Wood

– Durability: Prone to rot and insects, lasts 5-10 years with maintenance.

– High Maintenance: Requires annual painting/sealing, increasing costs.

– Environmental Impact: Uses chemical preservatives, less eco-friendly.

5. How to Choose the Right WPC Fencing?

– Privacy Needs: Fully enclosed for villas/pools; semi-enclosed for gardens.

– Aesthetic Goals: 3D embossed or co-extruded panels for wood-like appeal.

– Environment: UV-resistant, co-extruded WPC for coastal or sunny areas.

Application Spaces

– Residential: Privacy fences for backyards (e.g., 150x20mm panels).

– Public Parks: Open picket or trellis for pathways and greenery.

– Commercial: Durable, low-maintenance fences for hotels and offices.

WPC Factory Packaging Process and Shipping

At KINWIN, we understand the importance of packaging and shipping for WPC products. Our packaging process is designed to protect your products, ensuring they arrive in perfect condition.

Packaging Process

Our WPC products are carefully packaged using two main methods: woven bags and palletizing, ensuring safety during transportation.

Woven Bags

WPC products are first placed in durable woven bags made from high-strength polypropylene, with a capacity of up to 50 kg. Each bag includes a moisture-resistant liner to protect against humidity.

– Material: Polypropylene

– Weight Capacity: 50 kg

– Dimensions: 90cm x 60cm x 30cm

– Strong woven bags safeguard your products from damage.

– Moisture resistance keeps products intact in any condition.

Palletizing

Woven bags are neatly stacked on wooden pallets, each capable of holding up to 1000 kg. Plastic straps and stretch film are used to secure the products, preventing movement during transit.

– Pallet Type: Wooden pallets

– Weight Capacity: 1000 kg

– Products per Pallet: 20 woven bags

– Secure pallets improve loading and unloading efficiency.

– Securing methods ensure stability during shipping.

Shipping

Our shipping process ensures your WPC products reach you safely and on time.

Quality Checks

Before shipping, we conduct a final quality check to ensure packaging integrity and accurate product counts, meeting high standards.

– Rigorous checks ensure you receive flawless products.

Loading

Packaged products are carefully loaded onto trucks or containers using forklifts and manual equipment for a safe and efficient process.

– Professional loading minimizes damage risks during transit.

Shipping Methods

We offer flexible shipping options:

– Sea Freight: Ideal for international orders, cost-effective.

– Air Freight: Best for urgent orders, quick delivery.

– Sea Freight Time: 15-30 days

– Air Freight Time: 1-3 days

– Multiple options meet your project timelines.

Conclusion

At [Company Name], we ensure your WPC products arrive safely with professional woven bags, palletizing, and flexible shipping options. Contact us today to learn more or place your order!

Project-based one-stop service

Choose the Right WPC Easily

Not sure which WPC to pick? No worries! Our experts guide you to the best WPC products based on your project needs like usage, load, and design.

Perfect Accessory Match

We recommend screws, adhesives, and more that work perfectly with your WPC for a smooth, durable installation.

Ready-Made Specification Guide

We offer ready-made specification documents and guides to help you prepare project files quickly and avoid mistakes.

Professional Bidding Support

Our team reviews your bidding documents and gives pricing and material tips to help you win bids.

Precise Material Calculation

We calculate the exact amount of WPC and accessories you need, so you don’t overbuy and save on project costs.

How to identify high-quality WPC

Choose a reliable brand

Worried about picking unreliable WPC products? No worries! Choose manufacturers with a good reputation, check for ISO or ASTM certifications, and read customer reviews to ensure reliability and avoid future issues.

– Manufacturer reputation: It is recommended to choose a company with more than 10 years of experience.

– Certification: ISO 9001, ASTM D7031, etc.

– Customer reviews: Check the ratings on websites or third-party platforms such as Trustpilot.

Check the material composition

Confused about WPC materials? Don’t worry! Check for HDPE plastic, note the wood-to-plastic ratio, and ensure UV stabilizers are included for durability and aesthetics, perfect for long-term use.

– Plastic type: HDPE is preferred for durability.

– Wood content: usually 60-70% plastic, 30-40% wood fiber.

– Additives: UV stabilizers, pigments, coupling agents, etc.

Evaluation performance indicators

Concerned about strength or water absorption? Relax! Check density (>0.9 g/cm³), water absorption (<2%), and strength (>30 MPa); high-density, low-absorption products last longer, protecting your investment.

– Density: recommended to be greater than 0.9 g/cm³.

– Water absorption rate: less than 2% (ASTM D570).

– Mechanical strength: flexural strength>30 MPa (ASTM D7031).

Check the appearance quality

Want a good-looking product? Easy! Check for a smooth surface, consistent color, and feel the weight to gauge density; it enhances project quality and aesthetics.

– Surface inspection: no cracks, bubbles, uneven color.

– Weight comparison: for products of the same size, the heavier one may have a higher density.

Get real feedback

Want to know real performance? Read customer reviews to learn about durability and maintenance; real feedback helps you choose wisely.

– Evaluation sources: manufacturer website, Trustpilot, X platform, etc.

– Focus: durability, maintenance cost, ease of installation.

Ensure after-sales protection

Worried about after-sales support? Choose products with long warranties (5+ years) and reliable support for worry-free use.

– Warranty period: It is recommended to choose more than 5 years.

– Support channels: phone, email, online chat.

Verified Quality Certification

Need more quality proof? Ask for test reports or certifications to verify performance; official reports build trust and ensure project success.

– Test Standards: ASTM D570 (Water Absorption), ASTM G155 (Weathering).

– Report Type: Independent Laboratory Certification Report.

1. How durable is WPC fencing compared to traditional wood fencing?

WPC fencing, made from 60% recycled wood fiber and 30% HDPE, resists rot, insects, and UV rays, lasting 15-25 years. Traditional wood fencing lasts 5-10 years and requires frequent maintenance, with 20% higher upkeep costs.

2. Is WPC fencing suitable for extreme weather conditions?

Yes, WPC fencing withstands temperatures from -40°C to 60°C, resists moisture, and remains stable in high winds (up to 120 km/h per ASTM tests), making it ideal for coastal or arid regions.

3. Can WPC fencing be customized for specific designs?

Absolutely, WPC fencing offers customizable colors (e.g., walnut, gray), textures (3D embossed or co-extruded), and sizes (e.g., 150x20mm panels), catering to privacy, trellis, or picket styles for gardens or commercial spaces.

4. How easy is it to install WPC fencing?

WPC fencing is DIY-friendly, using modular panels and aluminum posts with stainless steel clips. Installation takes 30% less time than wood fencing, with global installation costs averaging $2-4 per square foot in 2023.

5. Is WPC fencing eco-friendly?

Yes, WPC fencing uses 60% recycled wood fiber and 30% recycled HDPE, is 100% recyclable, and complies with FSC and ISO14001 standards, reducing deforestation by 15% compared to traditional wood.

6. How long do WPC pergolas last compared to wooden pergolas?

WPC pergolas last 15-25 years, resisting rot, insects, and UV fading, while wooden pergolas last 5-12 years with regular maintenance, costing 25% more in upkeep per year.

7. Are WPC pergolas waterproof and suitable for humid climates?

Yes, WPC pergolas are 100% waterproof due to their HDPE and co-extruded layers, preventing warping or mold in humid climates, making them ideal for tropical or coastal areas.

8. Can WPC pergolas be customized for specific spaces?

WPC pergolas are highly customizable, offering open-roof, half-covered, or fully covered designs, with sizes (e.g., 3x3m, 4x4m) and colors (teak, charcoal) tailored for gardens, patios, or resorts.

9. How is a WPC pergola installed?

WPC pergolas use pre-fabricated kits with aluminum or WPC beams (e.g., 120x120mm) and stainless steel connectors, anchored to concrete with base plates. Installation is 20% faster than wood, averaging $500-1000 per unit in 2023.

10. Why is the WPC pergola market growing globally?

The WPC pergola market, valued at $1.2 billion in 2023, is growing at 7% annually due to rising demand for low-maintenance, eco-friendly outdoor structures, especially in Asia-Pacific and North America, driven by urbanization and outdoor living trends.

We're Ready to Collaborate with You

If you have any questions or need a quote, please send us a message. Our experts will respond within 24 hours to help you choose the right product for your needs.