Imagine installing a stunning new floor only to notice gaps or buckling a year later—frustrating, right? Expansion concerns are a hot topic for anyone considering SPC (Stone Plastic Composite) flooring, especially with its rising popularity in homes and businesses. Homeowners and designers alike search for answers to ensure their investment stays flawless. Does SPC flooring expand? SPC flooring is highly resistant to expansion and contraction due to its rigid stone-plastic core, offering superior stability compared to traditional flooring like hardwood or laminate. In this guide, we’ll dive deep into why SPC flooring is a game-changer, debunk myths, and share expert tips to keep your floors perfect. Stick with us as we unravel a real-life story of a homeowner who dodged a flooring disaster by choosing SPC—let’s get started!

1.What Is SPC Flooring and How Is It Made?

SPC flooring, or Stone Plastic Composite, is a rigid, waterproof vinyl flooring made with a limestone-plastic core, offering durability and stability. It’s crafted to mimic wood or stone but outperforms traditional materials in versatility.

Understanding SPC’s Composition

The Anatomy of SPC Flooring

SPC flooring consists of multiple layers:

- Wear Layer: Protects against scratches and stains.

- Vinyl Top Layer: Displays the design (wood, stone, etc.).

- SPC Core: A blend of limestone and PVC for rigidity.

- Underlayment: Adds cushioning and soundproofing.

Manufacturing Process

Advanced production involves high-pressure molding and UV coating, ensuring a dense, stable core. Our factory uses cutting-edge equipment to achieve precision, with each batch tested for quality.

Why SPC Stands Out

Unlike laminate, SPC is 100% waterproof, making it ideal for kitchens or bathrooms. Its click-lock system simplifies installation, reducing errors that could lead to expansion issues.

Critical Insight: The limestone-heavy core gives SPC its edge, minimizing thermal movement. However, not all SPC is equal—low-quality products may skimp on core density, risking instability. Always check manufacturer certifications.

| Component / Aspect | Details |

|---|---|

| Definition | SPC (Stone Plastic Composite) is a rigid, waterproof vinyl flooring with a stone-plastic core. |

| Core Advantage | Made of limestone + PVC, offering strength, minimal expansion, and water resistance. |

| Layer Structure | 1. Wear Layer – Scratch & stain protection 2. Vinyl Layer – Decorative print 3. SPC Core – Rigid stability 4. Underlayment – Sound & comfort support |

| Manufacturing Process | High-pressure compression, UV coating, precision engineering, and strict quality control. |

| Key Benefits | Waterproof, DIY-friendly click-lock system, dimensionally stable—great for kitchens/bathrooms. |

| Pro Tip | Always verify core density and certifications to avoid unstable, low-grade SPC products. |

2.Does SPC Flooring Expand or Contract?

SPC flooring rarely expands or contracts due to its stone-plastic core, which resists temperature and humidity changes better than hardwood or laminate. This stability makes it a top choice for diverse climates.

Why SPC Stays Stable

Thermal Stability Explained

SPC’s core has a low coefficient of thermal expansion, meaning it doesn’t significantly change size with heat or cold. Studies show SPC expands less than 0.01% per degree Celsius, compared to hardwood’s 0.05%.

Comparison with Other Flooring

| Flooring Type | Expansion Rate | Water Resistance | Best Use Case |

|---|---|---|---|

| SPC | Minimal (<0.01%) | 100% Waterproof | Any room |

| Hardwood | High (0.05%) | Low | Dry areas |

| Laminate | Moderate | Limited | Low-moisture |

| LVT Vinyl | Moderate | High | Bathrooms |

Real-World Performance

In a Florida home with high humidity, SPC flooring showed no gaps after two years, unlike hardwood that warped in similar conditions. This resilience stems from SPC’s inorganic composition.

Critical Insight: While SPC is stable, extreme conditions (e.g., direct sunlight or subzero temperatures) can cause minor movement. Choosing thicker SPC (6mm+) enhances stability further.

3.What Factors Influence SPC Flooring Expansion?

Temperature, humidity, and installation quality are the main factors affecting SPC flooring expansion, though its rigid core minimizes these risks. Proper setup is key to flawless performance.

Breaking Down the Influences

Environmental Conditions

High humidity or temperature swings can stress any flooring. SPC’s waterproof core resists moisture, but prolonged exposure to extreme heat (e.g., 140°F) may cause slight expansion.

Installation Methods

Floating SPC floors rely on click-lock systems, allowing minimal movement. Glue-down installations anchor the floor, reducing expansion risks but requiring a smoother subfloor.

Subfloor Quality

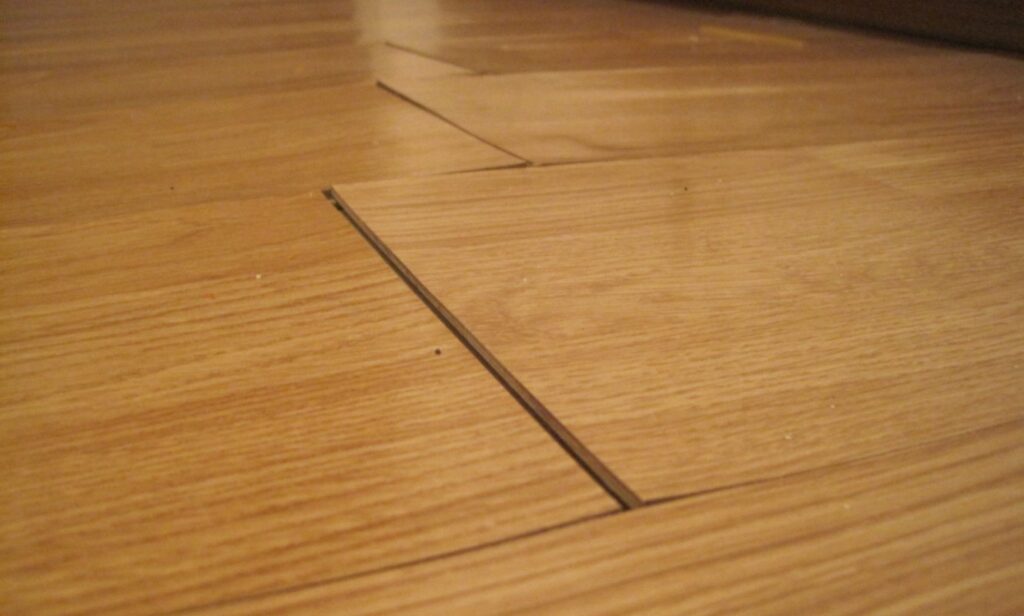

Uneven or damp subfloors can cause issues. For example, a client in Texas noticed minor buckling due to an unprepared concrete subfloor. Leveling and moisture barriers solved the problem.

Critical Insight: SPC’s stability doesn’t exempt it from poor installation. Always hire certified installers or follow manufacturer guidelines to avoid preventable issues.

| Factor | Description | Impact on Expansion |

|---|---|---|

| Temperature | Extreme heat (e.g., >140°F) may cause minor expansion. | Can lead to slight edge lifting or joint stress. |

| Humidity | High humidity adds moisture stress, especially in poorly ventilated areas. | May affect perimeter expansion if gaps are not left. |

| Installation Method | Click-lock allows limited movement; glue-down restricts it more effectively. | Poor technique = buckling or gaps; correct method = stable floor. |

| Subfloor Quality | Uneven or damp subfloors interfere with floor stability. | May cause buckling, noise, or improper locking. |

| Installer Expertise | Inexperienced installation may ignore expansion gaps or surface prep. | Increases risk of post-installation movement or warranty voiding. |

4.How Can You Prevent or Minimize SPC Flooring Expansion?

Prevent SPC flooring expansion by acclimating it for 48 hours, maintaining stable indoor conditions, and following proper installation guidelines. These steps ensure long-term performance.

Practical Prevention Tips

Acclimation Process

Before installation, store SPC planks in the room for 48 hours at 60-80°F. This adjusts the material to the environment, reducing post-installation movement.

Installation Best Practices

- Leave Expansion Gaps: Allow 1/8-inch gaps around walls to accommodate minor movement.

- Use Quality Underlayment: A moisture-resistant underlayment prevents subfloor issues.

- Check Subfloor Flatness: Ensure the subfloor is level within 3/16 inch per 10 feet.

Maintaining Indoor Conditions

Keep humidity between 35-65% and temperatures between 60-80°F. A dehumidifier in humid climates or a heater in cold ones can help.

Critical Insight: Overlooking acclimation or skipping expansion gaps is a common rookie mistake. Think of it like baking—skip a step, and the result flops.

| Preventive Step | Action | Why It Matters |

|---|---|---|

| Acclimate Flooring | Store planks in the installation room for 48 hrs at 60–80°F. | Reduces post-installation shifting due to temperature adjustment. |

| Leave Expansion Gaps | Allow 1/8-inch gaps around walls and fixed objects. | Provides space for natural expansion and contraction. |

| Use Quality Underlayment | Choose moisture-resistant underlayment. | Prevents moisture from affecting the core or causing lifting. |

| Check Subfloor Flatness | Subfloor should be level within 3/16 inch over 10 feet. | Prevents pressure points and misalignment that lead to buckling. |

| Control Indoor Conditions | Maintain 35–65% humidity and 60–80°F temperature year-round. | Prevents environmental stress from affecting floor stability. |

5.Are There Specific SPC Flooring Products Designed for Stability?

SPC flooring with thicker cores (6mm+) and advanced locking systems offers superior stability against expansion. Our factory’s products prioritize these features for reliability.

Choosing Stable SPC Flooring

Key Features for Stability

- Thicker Cores: 6-8mm SPC resists movement better than 4mm options.

- Locking Systems: Patented click-locks (e.g., Uniclic) ensure tight seams.

- High-Density Core: Our SPC uses 70% limestone for added rigidity.

Our Factory’s Solutions

Our SPC flooring line, crafted with eco-friendly materials, includes 7mm-thick options with UV-coated wear layers. These are ideal for commercial spaces with heavy foot traffic.

Application-Specific Products

For high-moisture areas, our HydroGuard SPC line features enhanced waterproofing. In a recent project, a gym in California used this product, reporting zero expansion after a year.

Critical Insight: Not all SPC flooring is created equal. Budget brands may cut corners on core density, so prioritize certified manufacturers like ours for peace of mind.

| Stability Feature | Description | Why It Matters |

|---|---|---|

| Thicker Cores (6–8mm) | Greater core thickness reduces flex and thermal expansion. | Offers better dimensional stability, especially in high-traffic areas. |

| Advanced Locking Systems | Uses systems like Uniclic or Valinge for secure, gap-free installation. | Prevents seam separation and enhances overall floor performance. |

| High-Density Core (70%+ limestone) | Increases weight and rigidity of each plank. | Resists warping, especially in extreme environments. |

| UV-Coated Wear Layer | Protects against surface wear and sunlight damage. | Maintains appearance and integrity over time. |

| HydroGuard Options | Specially engineered for moisture-prone areas. | Zero expansion reported even in high-humidity environments like gyms. |

6.Common Myths and Misconceptions About SPC Flooring Expansion

SPC flooring isn’t immune to expansion, but its minimal movement is often exaggerated. Quality products and proper installation debunk most myths.

Busting the Myths

Myth 1: SPC Never Expands

While SPC is highly stable, extreme conditions can cause slight movement. However, this is rare and manageable with proper care.

Myth 2: All SPC Performs the Same

Low-quality SPC with thin cores or weak locking systems may buckle. Our factory’s rigorous testing ensures consistent performance.

Myth 3: SPC Doesn’t Need Acclimation

Skipping acclimation can lead to minor issues. A client in New York learned this the hard way when rushed installation caused slight gapping.

Critical Insight: Myths often stem from misinformation or poor experiences with subpar products. Stick to reputable brands to avoid headaches.

Conclusion

SPC flooring is a stellar choice for anyone seeking durability, style, and minimal expansion concerns. Its stone-plastic core offers unmatched stability, making it perfect for homes, offices, or industrial spaces. By choosing high-quality SPC and following expert installation tips, you can enjoy flawless floors for years. At Kinwin, we’re passionate about crafting eco-friendly, high-performance SPC flooring tailored to your needs. Ready to transform your space? Contact Kinwin today to request a quote or customize your perfect flooring solution. Let’s build something beautiful together!