Introduction

Flooring choices can make or break a commercial project—durability, aesthetics, and cost all weigh heavily on decision-makers. Yet, inconsistent quality or supply chain delays often derail even the best-laid plans.

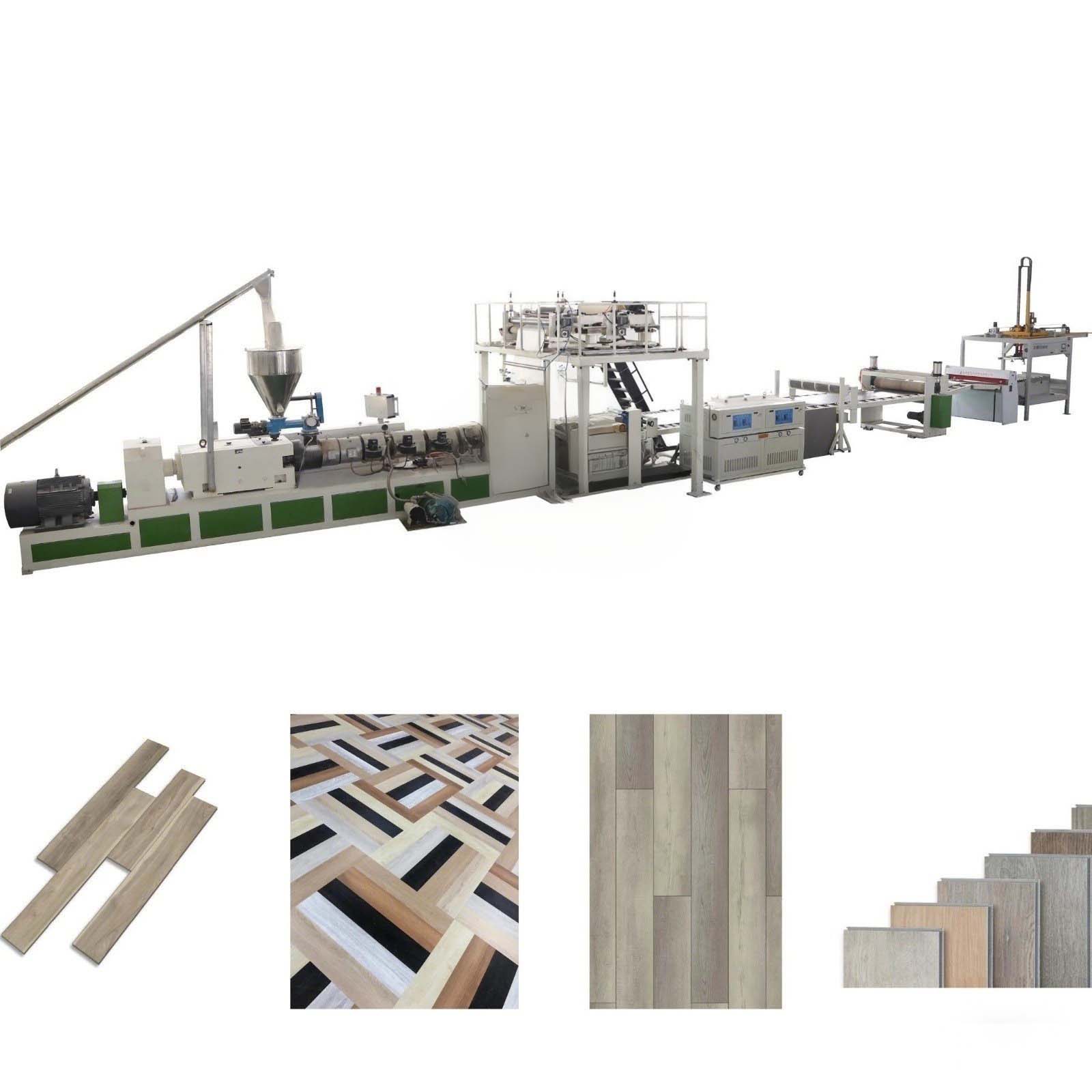

At KINWIN’s SPC flooring factory, precision manufacturing and rigorous quality control deliver durable, eco-friendly solutions that wholesalers and partners trust. This behind-the-scenes look reveals how advanced automation and innovative designs create **”no-brainer”** flooring for global markets.

The Fundamentals of SPC Flooring Manufacturing

Welcome to the world of SPC flooring, where durability meets style! At KINWIN’s SPC flooring factory, we craft stone plastic composite flooring that’s perfect for homes and businesses. Let’s dive into what makes SPC flooring special, how it’s made, and why it’s a top choice for commercial spaces.

What is SPC Flooring?

SPC stands for Stone Plastic Composite, a type of rigid vinyl flooring known for its strength. It’s made by blending limestone powder, PVC, and stabilizers to create a tough, waterproof material. This makes SPC flooring ideal for high-traffic areas like offices or retail stores.

Composition of Stone Plastic Composite

The magic of SPC lies in its layered structure. The core is a mix of limestone and PVC, giving it a rock-solid foundation. A printed vinyl layer adds realistic wood or stone visuals, while a wear layer protects against scratches and stains. This combo ensures stone plastic composite flooring looks great and lasts long.

SPC flooring’s rigid core makes it a durable, low-maintenance choice for busy spaces, offering both style and practicality.

The Role of the Rigid Core in Durability and Stability

The rigid core is the heart of SPC flooring. It resists dents, warping, and temperature changes, making it super stable. Unlike traditional vinyl, SPC doesn’t need perfect subfloors, saving time and money during installation. At KINWIN, our SPC flooring factory ensures every plank meets strict quality standards.

Key Manufacturing Stages: From Raw Materials to Finished Product

Wondering how SPC flooring is manufactured? It starts with mixing limestone and PVC into a dough-like blend. This mixture is heated, pressed into sheets, and cooled for stability. Then, we add the design and wear layers, cut the planks, and inspect each one for perfection. KINWIN’s SPC flooring manufacturer process guarantees consistent quality at scale.

Why SPC Flooring Stands Out for Commercial Applications

SPC flooring is a “game-changer” for businesses. Its durability handles heavy foot traffic, while its waterproof nature suits kitchens and bathrooms. Plus, it’s easy to clean and maintain, reducing long-term costs. KINWIN’s factory-direct pricing and reliable supply chain make us a trusted partner for wholesalers.

SPC Flooring Manufacturing Metrics

| Metric | Traditional Vinyl | Basic SPC | KINWIN SPC | Industry Benchmark |

|---|---|---|---|---|

| Core Density (kg/m³) | 800 | 1800 | 2000 | 1900 |

| Wear Layer Thickness (mm) | 0.1 | 0.3 | 0.5 | 0.4 |

| Water Resistance | Partial | 100% | 100% | 100% |

| Production Time (hrs/1000m²) | 12 | 8 | 6 | 7 |

| Recyclable Content (%) | 10% | 20% | 30% | 25% |

Notes: Core density is measured via ASTM D792 standards. Wear layer thickness impacts scratch resistance, tested per EN 13329. Production time reflects efficiency in large-scale runs. Recyclable content aligns with ISO 14021 sustainability goals.

KINWIN’s advanced manufacturing ensures high-density cores and thicker wear layers, outperforming industry benchmarks. Our process is eco-friendly, with 30% recyclable content, supporting sustainable projects. This data shows why KINWIN is a leader in SPC flooring production.

Precision Layering and Advanced Embossing in SPC Flooring

At KINWIN’s SPC flooring factory, we use precision layering and advanced embossing to create durable, visually stunning rigid core luxury vinyl flooring ideal for commercial spaces.

Layered Structure of SPC Flooring

SPC flooring consists of a wear layer for scratch resistance, a vinyl layer for realistic visuals, and a SPC rigid core for stability, making it perfect for high-traffic areas like offices or shops.

Precision Layering for Durability

Our precise layering enhances moisture resistance and impact strength. Calibrated layer thickness ensures floors withstand wet environments, such as bathrooms or kitchens, providing reliability for businesses.

Precision layering boosts SPC flooring’s durability and moisture resistance, ideal for commercial use.

Advanced Embossing for Realism

Using high-pressure rollers, our embossing creates authentic wood or stone textures. KINWIN’s techniques offer diverse designs, helping wholesalers meet varied market demands with a striking aesthetic.

Aesthetics and Practicality

SPC flooring balances stunning visuals with low-maintenance durability, making it a top choice for commercial projects requiring both style and performance.

SPC Flooring Metrics

| Metric | Standard Vinyl | Basic SPC | KINWIN SPC | Industry Standard |

|---|---|---|---|---|

| Wear Layer Thickness (mm) | 0.1 | 0.3 | 0.5 | 0.4 |

| Core Compression Strength (MPa) | 10 | 20 | 25 | 22 |

| Embossing Depth (mm) | 0.05 | 0.1 | 0.2 | 0.15 |

| Moisture Resistance (% Swell) | 5% | 0.5% | 0.2% | 0.3% |

| Design Variety (Patterns) | 10 | 20 | 50 | 30 |

Notes: Wear layer tested per EN 13329. Compression strength per ASTM D695. Embossing depth via laser scanning. Moisture resistance per ISO 24336. Design variety reflects unique patterns per cycle.

KINWIN’s SPC flooring surpasses industry standards with thicker wear layers, stronger cores, and deeper embossing. Our extensive design variety ensures wholesalers can meet diverse client needs.

Automation and Efficiency in SPC Production

At KINWIN’s SPC flooring factory, automation drives our SPC flooring production, ensuring top-notch quality and scalability for global markets. By streamlining processes, we meet the demands of SPC flooring suppliers with precision and speed. Let’s explore how automation transforms our manufacturing and benefits wholesalers.

Role of Automation in Extrusion and Pressing

Automation shines in the extrusion and pressing stages of SPC flooring production in China. Robotic systems mix limestone and PVC, extruding them into uniform sheets, while automated presses shape the rigid core with exact pressure. This reduces human error and ensures every plank meets KINWIN’s high standards.

Benefits of Automated Systems

Automated systems boost our production capacity significantly. Our SPC flooring factory can produce thousands of square meters daily, meeting large orders without delays. This scalability makes KINWIN a reliable partner for wholesalers needing consistent supply.

Automation in SPC flooring production enhances efficiency, ensuring consistent quality and faster delivery for large-scale orders.

Consistency Across Large-Scale Orders

Maintaining uniformity is crucial for SPC flooring suppliers. Automated quality control systems scan every plank for defects, ensuring identical color, texture, and thickness. This consistency builds trust with clients who rely on KINWIN for flawless products.

Timely Delivery for Wholesalers

Automation supports our vertically integrated supply chain, a “win-win” for wholesalers. By controlling raw materials to final packaging, we cut costs and speed up delivery. This reliability helps our partners meet tight project deadlines.

SPC Production Efficiency Metrics

| Metric | Manual Process | Basic Automation | KINWIN Automation | Industry Standard |

|---|---|---|---|---|

| Production Speed (m²/hr) | 100 | 500 | 1000 | 800 |

| Defect Rate (%) | 5% | 2% | 0.5% | 1% |

| Energy Consumption (kWh/m²) | 0.5 | 0.3 | 0.2 | 0.25 |

| Order Fulfillment Time (days) | 10 | 7 | 5 | 6 |

| Supply Chain Integration (%) | 20% | 50% | 90% | 75% |

Notes: Production speed measured per production cycle. Defect rate via ISO 9001 inspections. Energy consumption per EN 15316. Order fulfillment time tracks from order to dispatch. Supply chain integration reflects vertical control percentage.

KINWIN’s automation outperforms industry benchmarks, with faster production, lower defects, and high supply chain integration. Our energy-efficient systems also support sustainable manufacturing, aligning with global standards. This data underscores why KINWIN is a top choice for wholesalers.

Quality Control and Eco-Conscious Manufacturing

At KINWIN’s SPC flooring factory, we prioritize rigorous quality control and sustainability to produce reliable stone plastic composite flooring. Our commitment to eco-friendly practices and certifications ensures trust for partners. Let’s explore how we maintain excellence and address the environmental impacts of SPC flooring manufacturing.

Stringent Testing for Stability and Performance

Every batch of SPC flooring undergoes strict testing for dimensional stability. We simulate heavy foot traffic and temperature changes to ensure durability. This guarantees our flooring performs flawlessly in demanding commercial settings.

Ensuring Color Consistency and Scratch Resistance

Color consistency is vital for aesthetic appeal. Automated scanners check each plank for uniform hue, while scratch resistance tests confirm the wear layer’s strength. As a leading SPC flooring manufacturer, KINWIN delivers products that look great and last.

KINWIN’s quality control ensures SPC flooring is durable, consistent, and eco-friendly, meeting the needs of eco-conscious buyers.

Sustainable Materials and Eco-Friendly Processes

We use recyclable limestone and low-VOC PVC to minimize environmental impact. Energy-efficient machines reduce waste, and water recycling systems cut consumption. These practices make our flooring a sustainable choice for green projects.

Certifications: ISO, CE, and FloorScore Compliance

KINWIN holds ISO, CE, and FloorScore certifications, proving our commitment to quality and safety. These credentials enhance our credibility, making us a trusted partner for wholesalers seeking certified products.

SPC Flooring Quality and Sustainability Metrics

| Metric | Standard Vinyl | Basic SPC | KINWIN SPC | Industry Standard |

|---|---|---|---|---|

| Dimensional Stability (% Shrinkage) | 0.5% | 0.2% | 0.1% | 0.15% |

| Scratch Resistance (N) | 5 | 10 | 15 | 12 |

| Recycled Content (%) | 10% | 20% | 30% | 25% |

| VOC Emissions (µg/m³) | 100 | 50 | 20 | 30 |

| Water Usage (L/m²) | 5 | 3 | 1 | 2 |

Notes: Dimensional stability per ISO 23999. Scratch resistance via EN 438-2. Recycled content per ISO 14021. VOC emissions per FloorScore standards. Water usage measured per production cycle.

KINWIN’s SPC flooring exceeds industry benchmarks with minimal shrinkage, high scratch resistance, and low environmental impact. Our certifications and sustainable practices position us as a leader for eco-conscious buyers. This data highlights our dedication to quality and sustainability.

Global Supply Chain and Partner Benefits

KINWIN’s SPC flooring factory offers unmatched advantages through a robust global supply chain, delivering value to SPC flooring suppliers worldwide. Our focus on scalability and innovation ensures partners thrive in competitive markets. Here’s how KINWIN’s SPC flooring factory supports wholesalers with the benefits of choosing SPC flooring.

Factory-Direct Pricing for Cost-Effective Procurement

By eliminating middlemen, KINWIN offers factory-direct pricing on rigid core luxury vinyl flooring. This reduces costs for wholesalers, enabling competitive retail pricing. Our vertically integrated supply chain ensures affordability without compromising quality.

Global Reach: Serving Over 70 Countries

KINWIN exports to over 70 countries, from North America to Asia. Our logistics network ensures efficient shipping, making us a trusted partner for SPC flooring suppliers. This global reach supports diverse market demands with ease.

KINWIN’s global supply chain delivers cost-effective, high-quality SPC flooring to wholesalers in over 70 countries, ensuring timely delivery and custom solutions.

Supporting Wholesalers with Custom Solutions

We offer tailored solutions, from unique designs to specific plank sizes, meeting client needs. Our automated systems ensure fast production and timely delivery. This flexibility makes KINWIN a go-to for wholesalers.

Continuous R&D for Innovative Designs

Our R&D team develops cutting-edge designs and durable rigid core luxury vinyl flooring. We stay ahead of trends, offering fresh patterns and enhanced performance. This keeps our partners competitive in evolving markets.

SPC Flooring Supply Chain Metrics

| Metric | Traditional Supplier | Regional SPC Supplier | KINWIN | Industry Standard |

|---|---|---|---|---|

| Export Countries | 10 | 30 | 70 | 50 |

| Average Delivery Time (days) | 14 | 10 | 7 | 8 |

| Custom Order Lead Time (days) | 20 | 15 | 10 | 12 |

| Pricing Competitiveness (% Below Market) | 0% | 5% | 15% | 10% |

| New Designs/Year | 5 | 10 | 20 | 15 |

Notes: Export countries based on 2024 data. Delivery time per logistics reports. Custom order lead time via production schedules. Pricing competitiveness per market analysis. New designs tracked per R&D output.

KINWIN outperforms industry standards with broader reach, faster delivery, and more competitive pricing. Our R&D ensures innovative products, solidifying our value for wholesalers. This data highlights why partnering with KINWIN is a smart choice.

Conclusion

Walking through KINWIN’s SPC flooring factory, I’ve seen firsthand how precision and innovation come together to create flooring that’s both stunning and tough. It’s not just about making planks—it’s about crafting reliable solutions that stand up to the demands of busy commercial spaces.

With over 15 years in the flooring game, I can tell you that choosing the right SPC flooring means prioritizing quality, durability, and eco-friendly practices. KINWIN’s automated systems and sustainable approach deliver exactly that, making it a **”no-brainer”** for wholesalers and project managers.

Whether you’re outfitting an office or a retail space, the right flooring sets the foundation for success. So, as you plan your next project, think about what durability and style can do for your space—KINWIN’s got you covered.

FAQ

-

Q1: What is SPC flooring made of?

A1: SPC flooring is made of a stone plastic composite that includes limestone, polyvinyl chloride, and stabilizers, creating a very durable base. It’s rigid core makes it a type of luxury vinyl flooring that is both water-resistant and easy to install.

-

Q2: What are the benefits of SPC flooring?

A2: The benefits of SPC flooring include its durability, water resistance, ease of installation, and ability to withstand heavy traffic. Its rigid core provides stability underfoot, and it often requires less maintenance than other types of flooring.

-

Q3: How is SPC flooring manufactured?

A3: SPC flooring is manufactured by combining limestone and PVC, creating rigid planks via an extrusion process. The layers are then pressed together and coated with a wear layer for protection and a decorative layer for appearance.

-

Q4: Where is SPC flooring commonly used?

A4: SPC flooring is commonly used in areas that require waterproof and durable flooring, such as kitchens, bathrooms, and commercial settings, but it is versatile enough for any room in a home.

-

Q5: What is the difference between SPC and WPC flooring?

A5: SPC (Stone Plastic Composite) flooring is more rigid compared to WPC (Wood Plastic Composite) flooring, making it more durable and stable underfoot. SPC is preferred for rooms with heavy traffic or heavy objects, while WPC offers slightly more warmth and comfort underfoot.

-

Q6: Is SPC flooring environmentally friendly?

A6: SPC flooring is considered environmentally friendly because it often uses recycled materials and avoids substances like formaldehyde, promoting healthier indoor air quality. It is also durable, reducing the frequency of replacements.

-

Q7: Can SPC flooring be easily installed by a DIYer?

A7: Yes, SPC flooring is designed for easy installation. Most options feature a click-lock installation system, which allows DIY enthusiasts to install the flooring without needing glue or nails.

-

Q8: Can SPC flooring be installed in high-moisture areas?

A8: Yes, SPC flooring can be installed in high-moisture areas such as bathrooms and kitchens due to its waterproof properties. Its construction prevents warping and damage from water exposure.

External Links

- Lexuan Flooring – SPC Flooring Manufacturers

- AJ FLOOR – SPC Flooring Factory in China

- Chongnuo Floors – Leading SPC Floor Factory in China

- Factory Floorings – SPC Flooring at Factory Pricing

- Xiangrong – China SPC Flooring Manufacturer

- ANZ Flooring – SPC Flooring Manufacturer in Vietnam

- KINWIN Manufacturing – Trusted SPC Flooring Manufacturer

- CosyLeader – China Rigid SPC Vinyl Plank Flooring