SPC flooring, short for Stone Plastic Composite, is rapidly becoming a favorite in the flooring industry. Its exceptional durability, water resistance, and aesthetic appeal have made it a popular choice for both residential and commercial spaces. But what exactly is SPC flooring made of, and why does it stand out from other types of flooring?

SPC flooring consists of a rigid stone-plastic composite core, a vinyl layer for design and durability, and a protective wear layer. This composition provides superior durability, moisture resistance, and an easy installation process, making it a preferred choice for many.

SPC flooring is more than just a tough surface—it’s a revolution in the way we think about durable and sustainable flooring options. Whether you’re renovating your home, outfitting a commercial space, or simply looking for a flooring solution that meets both aesthetic and functional demands, understanding what SPC flooring is made of is essential to making the right decision. Let’s dive into the details of its composition and discover why this material is taking the flooring world by storm.

1. What Are the Key Components of SPC Flooring?

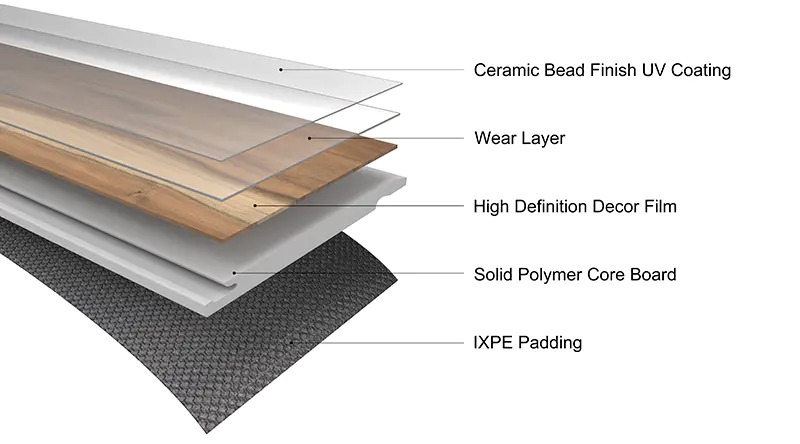

SPC flooring is a multi-layered, rigid core vinyl flooring system that stands out for its superior strength and stability. It is made of several key components: a stone-plastic composite core, a vinyl layer, and a protective wear layer. Each of these components plays a vital role in providing the flooring’s impressive performance.

SPC flooring consists of three main layers: a stone-plastic composite core, a vinyl top layer, and a wear-resistant layer. These layers work together to provide stability, durability, and aesthetic flexibility.

- Stone-Plastic Composite Core: The core of SPC flooring is made from a mixture of natural limestone powder, PVC, and stabilizers. This combination creates a rigid structure that enhances the flooring’s stability and resistance to wear, making it ideal for high-traffic areas.

- Vinyl Layer: The vinyl layer is printed with various designs, allowing SPC flooring to mimic the appearance of natural materials like wood, stone, or ceramic. This layer also adds flexibility and water resistance to the flooring.

- Wear Layer: The topmost layer is a protective wear layer that shields the flooring from scratches, stains, and fading. It ensures that the floor maintains its aesthetic appeal for years, even in busy spaces.

| Component | Description |

|---|---|

| Stone-Plastic Composite | Provides a rigid and stable core, enhancing durability |

| Vinyl Layer | Printed with design, providing aesthetic versatility |

| Wear Layer | Protects the surface from wear, scratches, and stains |

2. How Is the Stone Plastic Composite (SPC) Core Manufactured?

The SPC core is the backbone of SPC flooring, providing its rigidity and strength. This core is made by combining limestone powder, PVC, and various stabilizers through a heat extrusion process. The result is a dense, stable, and waterproof material that contributes to the overall durability of the flooring.

The SPC core is manufactured by mixing limestone powder with PVC and stabilizers. This mixture is then extruded into a rigid, stone-like core that provides the flooring with added stability and moisture resistance.

- Composition of the Core: The main ingredient in the SPC core is limestone powder, which makes up a significant percentage of the material. This powder is combined with PVC (polyvinyl chloride) and stabilizers to form a solid, dense core. The use of limestone makes the core rigid and strong, preventing expansion or contraction due to changes in temperature or humidity.

- Extrusion Process: The mixture is heated and extruded through a mold to form the desired shape and thickness of the core. This process ensures that the core is perfectly smooth and free of any imperfections, providing a stable foundation for the rest of the flooring layers.

- Benefits of the SPC Core: The rigid SPC core is what sets this flooring apart from traditional vinyl flooring. It is impervious to water, highly impact-resistant, and does not expand or contract like some other materials, making it ideal for areas with fluctuating moisture levels.

| Step | Process Description |

|---|---|

| Composition | Limestone powder, PVC, and stabilizers are mixed together |

| Extrusion | The mixture is heated and extruded into a rigid core |

| Benefits | The core provides strength, water resistance, and stability |

3. What Is the Role of the Vinyl Layer in SPC Flooring?

The vinyl layer in SPC flooring serves multiple purposes, most importantly its role in providing the floor with its visual appeal. This layer is printed with various designs, allowing SPC flooring to mimic the look of wood, stone, or tile. Additionally, the vinyl layer contributes to the flooring’s water resistance and ease of maintenance.

The vinyl layer in SPC flooring provides design flexibility and enhances the floor’s water resistance. It is printed with a wide range of patterns, making SPC a versatile flooring option.

- Design Flexibility: The vinyl layer is printed with high-definition designs that replicate the appearance of natural materials, like hardwood or stone. This allows homeowners and business owners to achieve the look of expensive materials without the high cost or maintenance.

- Water Resistance: The vinyl layer is naturally resistant to water, making it an ideal flooring solution for kitchens, bathrooms, and other moisture-prone areas. When combined with the rigid SPC core, the vinyl layer ensures that the flooring remains stable even in high-humidity environments.

- Ease of Maintenance: Thanks to the smooth surface of the vinyl layer, SPC flooring is easy to clean and maintain. It resists stains, scratches, and fading, ensuring that it retains its beauty with minimal upkeep.

| Feature | Description |

|---|---|

| Design Flexibility | Printed with wood, stone, or ceramic designs |

| Water Resistance | Ideal for wet areas, providing excellent protection against moisture |

| Maintenance | Easy to clean and resistant to stains and scratches |

4. Are There Different Types of SPC Flooring Available?

Yes, there are different types of SPC flooring that vary in terms of thickness, wear layer, and finish. These variations allow for customized solutions that cater to different environments and preferences.

SPC flooring comes in various thicknesses and finishes, including options with enhanced wear layers for commercial use or softer finishes for residential spaces.

- Thickness Options: SPC flooring is available in different thicknesses, typically ranging from 3mm to 8mm. Thicker options provide additional durability and sound insulation, making them suitable for high-traffic or commercial spaces.

- Wear Layer Variations: The wear layer, which is typically between 12mil to 30mil in thickness, determines how well the flooring can withstand heavy use. Thicker wear layers are often used in commercial spaces to ensure longevity.

- Surface Finish: SPC flooring comes in various surface finishes, such as matte, gloss, or embossed. These finishes not only enhance the aesthetics but also provide added texture and grip, improving the floor’s performance in certain areas.

| Type | Thickness | Wear Layer | Finish |

|---|---|---|---|

| Residential | 3mm-5mm | 12mil-20mil | Matte, Gloss, Embossed |

| Commercial | 5mm-8mm | 20mil-30mil | Embossed, Textured |

5. Which Materials Are Used in the Wear Layer of SPC Flooring?

The wear layer of SPC flooring is typically made from a clear, durable, and protective material, often a form of urethane or ceramic bead. This layer is what shields the floor from scratches, stains, and scuffs, ensuring that the flooring retains its look over time.

The wear layer of SPC flooring is made from durable materials like urethane and ceramic beads. It acts as a protective barrier, preventing damage and extending the lifespan of the flooring.

- Urethane Wear Layers: Urethane is a common material used for the wear layer due to its strength and resistance to scratches and stains. It provides a hard, smooth surface that is easy to clean.

- Ceramic Bead Additives: Some SPC flooring products include ceramic beads in the wear layer, which adds even more durability and resistance to abrasion. This is particularly beneficial for high-traffic areas like commercial spaces.

- Thickness of Wear Layer: The thickness of the wear layer is crucial in determining the longevity of the flooring. A thicker wear layer provides better protection against wear and tear, making it suitable for commercial and industrial environments.

| Material | Purpose |

|---|---|

| Urethane | Provides scratch resistance and easy cleaning |

| Ceramic Beads | Adds extra durability and abrasion resistance |

6. How Does SPC Flooring Compare to Other Flooring Materials?

SPC flooring offers a unique combination of durability, water resistance, and aesthetic flexibility. It stands out when compared to other popular flooring materials such as LVT, hardwood, and tile due to its superior structural integrity and ease of installation.

SPC flooring compares favorably with other flooring types in terms of durability, water resistance, and cost-effectiveness, particularly for high-traffic and moisture-prone areas.

- LVT vs SPC: While LVT is also a vinyl-based product, it tends to be more flexible and less durable than SPC, especially in high-traffic environments. SPC, with its rigid core, is more stable and resilient under heavy loads.

- Hardwood vs SPC: Hardwood is an elegant option but requires more maintenance, is susceptible to moisture damage, and comes at a higher price. SPC, on the other hand, offers the look of wood with better moisture resistance at a fraction of the cost.

- Tile vs SPC: Tile is durable but can be cold and hard underfoot. SPC flooring provides similar durability but with added comfort and noise reduction, making it ideal for homes and commercial spaces alike.

| Flooring Type | Durability | Water Resistance | Cost | Installation |

|---|---|---|---|---|

| SPC | High | Excellent | Affordable | Easy (Click-lock) |

| Hardwood | Moderate | Poor | Expensive | Complex (nailing) |

| Tile | High | Good | Moderate | Difficult (grouting) |

7. Are There Any Environmental Benefits to SPC Flooring?

SPC flooring is considered more eco-friendly than traditional flooring materials like hardwood or tile, largely due to its use of recyclable materials and the reduced need for harmful chemicals during manufacturing.

SPC flooring has environmental benefits, including the use of recyclable materials and lower energy consumption during production compared to traditional flooring options.

- Recyclable Materials: The primary component of SPC flooring, the stone-plastic composite core, is made from natural limestone powder, which is abundant and recyclable. The flooring itself is also recyclable, reducing waste over time.

- Energy Efficiency: SPC flooring is produced with lower energy consumption compared to other materials like tile or hardwood, making it a more sustainable option for large-scale construction projects.

- Non-Toxic Production: Unlike some flooring materials that require harmful chemicals, SPC flooring is manufactured with minimal chemical use, making it safer for both workers and consumers.

| Environmental Benefit | Description |

|---|---|

| Recyclability | Made from recyclable and natural materials |

| Energy Efficiency | Lower energy consumption during production |

| Non-Toxic Production | Minimal chemical use in manufacturing |

Conclusion

SPC flooring stands out in the flooring industry for its durability, water resistance, and aesthetic appeal. Made from a stone-plastic composite core, a vinyl layer, and a protective wear layer, SPC flooring offers a versatile and cost-effective solution for residential, commercial, and industrial spaces.

At Kinwin, we specialize in producing high-quality SPC flooring that meets the highest standards of performance, sustainability, and design flexibility. If you’re interested in learning more about our SPC flooring options or would like to request a custom quote, don’t hesitate to reach out to us today!