Hardwood still tugs at the heartstrings, tile screams “forever,” and laminate tempts our wallets—but none of those classics can claim to be simultaneously 100 % waterproof, pet-claw–proof, nearly indestructible, easy on the back, and friendly to weekend DIYers. Luxury vinyl flooring (LVF) can. That’s why analysts at Floor Covering Weekly reported LVF outsold laminate 3-to-1 in North America during 2024.¹

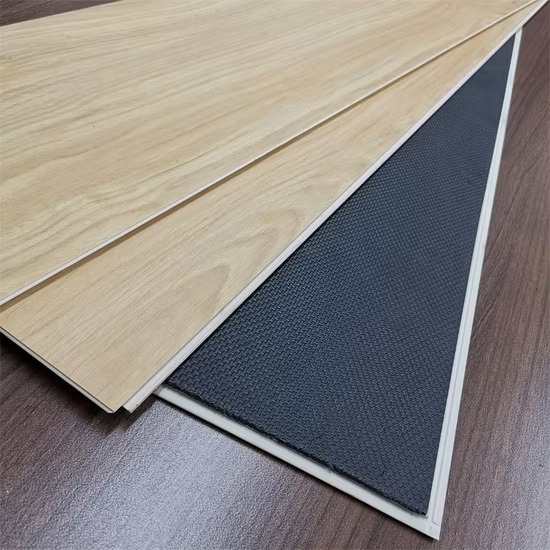

Luxury vinyl flooring combines a printed wood- or stone-design film with a clear wear layer fused to a waterproof vinyl or rigid-composite core and an acoustic backing. The result is a plank (LVP) or tile (LVT) that mimics natural materials, resists dents and moisture, installs with simple click-lock joints or glue, and costs 30-50 % less than real hardwood or ceramic.

A quick “vinyl flooring” search still dredges up horror stories about peeling corners and yellowing sheets from decades past. That’s ancient history. Today’s LVF uses high-dpi printing, limestone-filled cores, and ceramic-bead wear layers—technology so advanced a New York pastry shop carts 400-lb ovens over its floor daily without leaving a scratch (true story; see section 3). Ready for a deep dive? Let’s decode every layer, statistic, and buzzword so you walk away a bona-fide LVF pro.

1. What Exactly Is Luxury Vinyl Flooring and How Is It Made?

LVF is a waterproof, multi-layer plank or tile—wear layer, décor film, composite core, and backing—hot-pressed, embossed, and UV-cured to deliver hardwood-realistic looks with commercial-grade durability.

1.1 LVF Layer-by-Layer

| Layer (Top ➞ Bottom) | Propósito | Espesor típico | Geeky Detail |

|---|---|---|---|

| Wear layer | Scratch, stain & UV shield | 6 – 28 mil (0.15 – 0.70 mm) | Up to ~40 % ceramic beads in premium lines |

| PU or Acrylic coating | Added slip resistance & gloss control | 0.02 mm | Matte (≈7 GU) ➞ piano-gloss (≈25 GU) |

| Décor film | Photo-real wood/stone image | 0.10 mm | Printed at 1,000+ DPI |

| Core (PVC, WPC, SPC) | Dimensional stability, dent resistance | 3 – 6 mm | SPC = ~70 % limestone |

| Balancing/Acoustic backing | Sound deadening, subfloor forgiving | 0.5 – 1.5 mm | IXPE foam cuts footfall by 16 dB |

1.2 Manufacturing Cheat Sheet

- Blend & Extrude (PVC resin ± limestone)

- Calendaring — rolls flatten core sheets to micron precision.

- Print Film Lamination — décor layer married to core.

- Embossing-in-Register — steel plates press texture exactly where knots appear.

- UV Curing — 8–10 lamps flash-harden the topcoat in seconds.

- Cut & Click — CNC routers mill click-lock profiles accurate to ±0.02 mm.

1.3 Why the “Luxury” Tag?

- Looks: Knots and mineral swirls line up down to the pixel.

- Performance: Passes ASTM F2199 dimensional-stability test (<0.1 % change at 150 °F).

- Feel: Integrated underlay keeps footfall quiet and warm compared to ceramic.

2. Which Core Technologies Differentiate Luxury Vinyl (Flexible PVC, WPC, SPC)?

Flexible cores bend, WPC adds cushion and sound dampening, SPC packs limestone for rock-solid stability—your choice affects weight, comfort, and temperature tolerance.

2.1 Flexible PVC Core

- Density: ~1,200 kg/m³.

- Hallmark: Bend a plank; it curves. Great where subfloors are pristine and budgets tighter.

- Watch-out: Can “telegraph” minor slab bumps.

2.2 WPC (Wood-Plastic Composite) Core

- Density: ~900 kg/m³ (20 % lighter).

- Foam Bubbles = Softer Step: Springs back 30 % more than SPC in ASTM F2420 compression tests.

- Ideal Rooms: Condo bedrooms, toddler nurseries.

2.3 SPC (Stone-Plastic Composite) Core

- Density: ~2,000 kg/m³—roughly the same as terra-cotta tile.

- Thermal Swing Champ: Only 0.05 % movement from -20 °C to 60 °C (heat-pump homes, sunrooms).

- Downside: Feels firmer; consider an extra area rug for play zones.

Quick-reference Table (copy-friendly)

| Métrica | PVC flexible | WPC | SPC |

|---|---|---|---|

| Mass (kg/m² @ 5 mm) | 6 | 4.5 | 10 |

| Static-load dent (psi)² | 250 | 300 | 450 |

| Sound transmission (IIC w/ underlay) | 55 | 68 | 62 |

| DIY cut tool | Utility knife | Utility knife | Score-&-snap or saw |

| Price (USD/ft²) | 1.75–3.25 | 2.20–3.90 | 2.70–4.80 |

² ASTM F970

3. How Do Wear-Layer Thickness and Surface Treatments Drive Real-World Longevity?

Choose ≥12 mil for active households; ≥20 mil with ceramic-bead coating for pets or light commercial—each extra mil roughly adds one year of scuff-free life.

3.1 “mil” Myth-Busting

- 8 mil (0.20 mm): guest rooms, Airbnbs changed every few seasons.

- 12 mil (0.30 mm): kids + medium dog.

- 20 mil (0.50 mm): Great Danes, office chairs, or retail foyers.

- 28 mil+: airports, grocery aisles.

3.2 Coating Cocktail

- Aluminum-oxide PU ➜ 30 % harder than standard PU.

- Ceramic-bead ➜ embeds micro-ceramics; Taber test jumps from 15,000 to 40,000 cycles.

- UV-Matte ➜ lowers glare; helps anti-slip to 0.42 COF wet.

3.3 The Pastry-Shop Story

Brooklyn bakery installed 8 mil WPC. Rolling racks carved visible lanes in 14 months. Replaced with 20 mil SPC; after three years, owner reports zero wheel rutting, citing “best ROI we’ve made under $5k.”

4. Are There Distinct Installation Methods for Luxury Vinyl Flooring?

Click-lock floats on most subfloors, glue-down anchors heavy loads, and loose-lay solves quick or temporary projects—each demands different prep rigor.

4.1 Click-Lock (Floating)

- Speed: 300 ft² by two DIYers in a Saturday.

- Subfloor Flatness Rule: ≤3 mm variation over 10 ft—test with 6-ft level.

- Pro Tip: Stagger end joints >6 in to boost seam strength.

4.2 Glue-Down

- Adhesive Types:

- Pressure-sensitive (PS)—still tacky, allows repositioning.

- Wet-set hard glue—zero creep under forklifts.

- Cure Time: 24 hrs light traffic, 72 hrs heavy.

- Failsafe: Roll with 100-lb roller every 100 ft².

4.3 Loose-Lay / Tape

- Planks weigh 10 lbs + and sport rubberized backing.

- Install: Perimeter double-sided tape + field laid free.

- Use-Cases: Temporary retail kiosks, apartment refreshes before listing.

| Install Mode | Avg. Labor (USD/ft²) | Lift-&-Replace Ease | Moist-Vapor Tolerance |

|---|---|---|---|

| Click-Lock | 1.00 | ★★★★☆ | Good (use 6-mil poly) |

| Glue-Down | 1.75 | ★☆☆☆☆ | Excelente |

| Loose-Lay | 0.75 | ★★★★★ | Feria |

5. What Styles, Textures, and Finishes Can You Choose From?

Luxury vinyl spans bleached oaks, hand-scraped walnuts, marble slabs, terrazzo chips, and even herringbone planks—finished smooth, lightly brushed, or deep-embossed for slip resistance.

5.1 Wood-Look Hall-of-Fame

| Trend | Key Traits | Room Pairings |

|---|---|---|

| Nordic White Oak | Wide 9″ planks, matte 7 GU sheen | Minimalist lofts, coastal cottages |

| Coffee-Stain Walnut | Rich chocolate grain, satin finish | Libraries, boutique hotels |

| Reclaimed Barn Pine | Heavy saw-marks, EIR texture | Farmhouse kitchens, cafés |

5.2 Stone & Tile Imitators

| Visual | Tile Size | Slip Rating (DSR) | Best Spots |

|---|---|---|---|

| Calacatta Marble | 12 × 24″ | 0.62 | Bathrooms, spas |

| Charcoal Slate | 18 × 36″ | 0.76 | Mudrooms, patios (enclosed) |

| Retro Terrazzo | 24 × 24″ | 0.65 | Fashion retail, salons |

5.3 Pattern Play

- Herringbone kits—left + right tongue profiles pre-boxed.

- Chevron click planks—45° ends, foolproof joints.

- Parquet “mix-n-match” panels—12″ modules form Versailles motifs.

Want Instagram-worthy drama? Run planks diagonally across a tiny powder room; the angle tricks the eye into seeing a bigger space.

6. How Does Luxury Vinyl Stack Up Against Laminate, Hardwood, and Tile?

LVF beats laminate on water, undercuts hardwood and tile on price, and offers softer, warmer steps—though hardwood still wins on refinishing longevity.

| Métrica | Vinilo de lujo | Laminate (AC4) | Solid Oak | Gres porcelánico |

|---|---|---|---|---|

| Material $/ft² (avg) | 2.50–4.50 | 1.80–3.50 | 6.00–11.00 | 4.50–9.00 |

| Impermeable | Sí | No | No | Sí |

| Dent Resistance (psi)³ | 300–450 | 250 | 145 | 500+ |

| Walking Noise (dB) | 52 | 60 | 55 | 68 |

| Resale Appeal | High (modern) | Moderado | Premium | Premium |

| Refinishing Cycles | 0 | 0 | 3–5 | 0 |

| Installation DIY | Fácil | Fácil | Challenging | Moderado |

³ Brinell hardness converted to static load resistance

7. When Is Luxury Vinyl the Smartest Choice—and What Should You Check Before Buying?

Opt for LVF in moisture-prone, budget-sensitive, or tenant spaces—verify wear-layer thickness, VOC certifications, warranty length, and match core type to climate before swiping the card.

7.1 Perfect Scenarios

- Basements & Baths—100 % waterproof, mold-resistant.

- Rental Flips—fast install, low downtime, easy plank replacement.

- Pet Palaces—scratch coatings outlast claws; wipe-clean accidents.

7.2 5-Point Buyer Checklist

- Traffic Reality: 20 mil if scooters, skateboards, or rolling tool chests roam.

- Core Logic: SPC for big windows or radiant-heat floors (≤82 °F); WPC for condos needing ≥IIC-65.

- VOC & Phthalates: Look for FloorScore® or GREENGUARD Gold logos.

- Warranty Fine Print: “Pet urine” and “sun-fade” often excluded in bargain brands.

- Spare Boxes: Buy 5–10 % extra; dye lots change every production run.

7.3 Red-Flag Pitfalls

- Skipping Acclimation: Even SPC benefits from 24 hr in-room rest.

- Edge Gaps < 6 mm: Floors can “smile” (peak) when summer humidity hits.

- Steam Mops: Can force hot vapor into seams, voiding warranties.

Need Help Choosing? Ping Kinwin for Samples & Quotes

By now you know luxury vinyl isn’t one-size-fits-all. Core density, wear-layer specs, embossing depth, and installation method all dictate how your floor will look y last. At Kinwin, we engineer every plank—flexible, WPC, or SPC—under strict ISO and FloorScore standards, using recycled limestone and low-VOC resins. Whether you manage 200 rental units or just want a spa-worthy ensuite, we’ll match you with the perfect LVF line.