SPC (Stone Plastic Composite) flooring has gained immense popularity in the construction and interior design industries due to its durability, water resistance, and aesthetic appeal. But just like any flooring material, questions arise about its performance in different environmental conditions. One of the most common concerns is whether SPC flooring expands or contracts, particularly when exposed to changes in temperature and humidity.

SPC flooring is relatively stable compared to other flooring materials, but it can expand and contract slightly due to temperature fluctuations or excessive moisture. The degree of expansion or contraction is minimal, and proper installation and maintenance can help mitigate these effects.

In this comprehensive guide, we’ll explore how SPC flooring reacts to environmental factors, how to prevent expansion and contraction issues, and how proper installation can ensure long-term stability. Read on to learn how to protect your SPC floors and keep them in top condition for years.

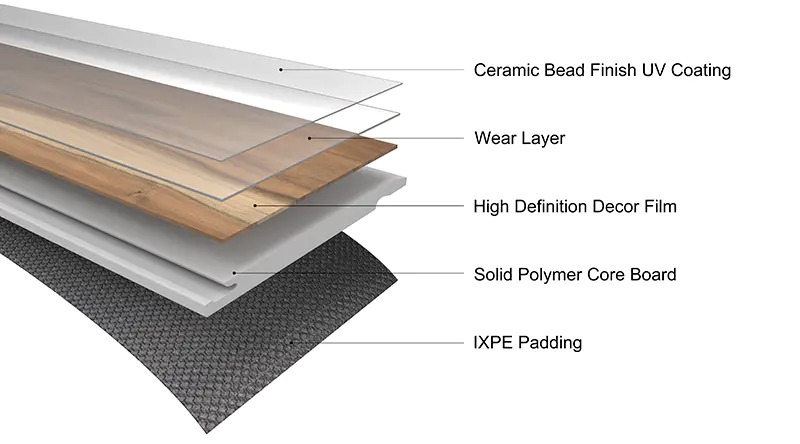

1. What is SPC Flooring Made of?

Before diving into whether SPC flooring expands or contracts, it’s important to understand the materials that make up SPC flooring and how they contribute to its stability.

SPC flooring consists of four main layers: a wear layer, a vinyl layer, a stone composite core, and a backing layer. The combination of these materials makes SPC flooring highly durable and relatively resistant to expansion and contraction.

- Wear Layer: This is the top layer of SPC flooring and is designed to resist scratches, stains, and wear. It is typically made from a transparent polyurethane material that enhances durability and protects the design layer beneath.

- Vinyl Layer: Beneath the wear layer, the vinyl layer provides the aesthetic look of the floor, often mimicking wood, stone, or other materials. The vinyl is flexible and helps the flooring withstand minor temperature or humidity changes.

- Stone Composite Core: The core of SPC flooring is made from a mixture of limestone and PVC. This dense core gives the flooring its rigidity and makes it more stable than other vinyl floors like WPC (Wood Plastic Composite).

- Backing Layer: The backing layer provides extra stability, support, and moisture resistance. It also helps to absorb sound and ensure the floor remains level over time.

| Layer | Material | Purpose |

|---|---|---|

| Wear Layer | Polyurethane or vinyl | Protects the surface from damage |

| Vinyl Layer | PVC and other polymers | Provides design and aesthetic flexibility |

| Stone Composite Core | Limestone and PVC | Adds rigidity, durability, and stability |

| Backing Layer | Foam or cork | Provides moisture resistance and cushioning |

2. Does SPC Flooring Expand or Contract Over Time?

SPC flooring is highly stable compared to traditional hardwood or laminate, but like all materials, it can experience slight expansion or contraction due to changes in environmental conditions.

While SPC flooring is stable, it may expand or contract slightly due to fluctuations in temperature and humidity. However, the degree of change is minimal, especially compared to other types of flooring.

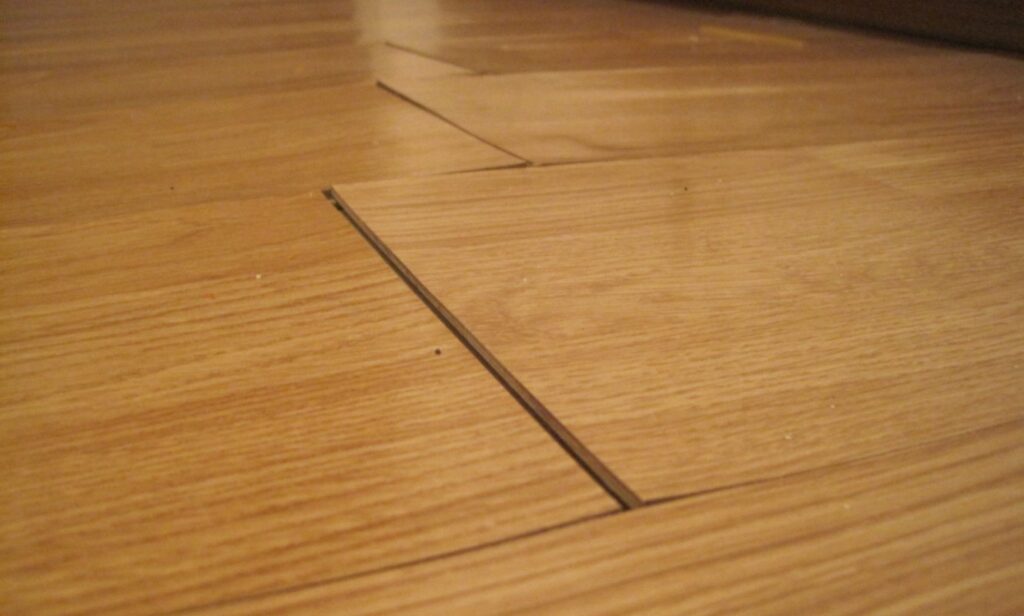

- Temperature Changes: SPC flooring is made of a combination of rigid materials, which means it is less likely to expand or contract significantly due to temperature changes compared to traditional wood flooring. However, extreme temperature changes can cause slight expansion or contraction, especially if the flooring is installed without the proper expansion gaps.

- Humidity: SPC flooring is moisture-resistant, but high humidity or excess moisture can cause the vinyl layers to absorb some water, leading to minor expansion. The stone composite core reduces the impact of moisture, making SPC flooring less susceptible to expansion than other materials like wood or laminate.

- Long-Term Use: Over time, with constant exposure to temperature and humidity changes, the flooring may experience slight shifts, but these changes are usually small and not noticeable unless the environment is extreme.

| Environmental Factor | Effect on SPC Flooring | Solution |

|---|---|---|

| Temperature | Minor expansion or contraction | Ensure proper installation and acclimation |

| Humidity | Slight expansion with moisture | Keep humidity levels controlled |

| Long-Term Use | Slight shifts in flooring position | Regularly check the condition and ensure proper installation |

3. Which Environmental Factors Affect the Expansion and Contraction of SPC Flooring?

While SPC flooring is generally stable, certain environmental factors can cause it to expand or contract over time. Understanding these factors is essential for minimizing any potential issues.

The primary environmental factors affecting SPC flooring are temperature, humidity, and the condition of the subfloor. These factors can all influence the flooring’s stability and should be considered during installation.

- Temperature Variations: Extreme heat or cold can cause any material, including SPC, to expand or contract. For example, a room exposed to direct sunlight or heat sources may cause the flooring to expand slightly. In contrast, colder environments may lead to contraction.

- Humidity and Moisture: High humidity levels can cause moisture to be absorbed by the flooring, leading to slight expansion. Similarly, excessive moisture from leaks or spills can cause damage to the flooring, leading to expansion or warping.

- Subfloor Conditions: A poorly prepared or uneven subfloor can exacerbate expansion and contraction issues. If the subfloor is not level or dry, it can cause uneven movement in the SPC flooring, leading to gaps or buckling over time.

| Factor | Effect on SPC Flooring | Recommended Action |

|---|---|---|

| Temperature | Expansion or contraction due to heat or cold | Install in climate-controlled spaces |

| Humidity | Expansion with moisture absorption | Control humidity and ensure adequate ventilation |

| Subfloor Condition | Uneven expansion or contraction | Prepare subfloor to be level and dry |

4. How Does the Quality of SPC Flooring Affect Its Expansion and Contraction?

The quality of SPC flooring can play a significant role in how it reacts to environmental factors. Higher-quality SPC materials tend to have better resistance to expansion and contraction.

The higher the quality of the SPC flooring, the less likely it is to experience noticeable expansion or contraction. High-quality SPC flooring is made from more durable materials and superior manufacturing processes.

- Material Composition: Higher-end SPC flooring typically uses a denser stone composite core, which helps prevent excessive movement. The vinyl layers in premium SPC flooring are also more stable and better at resisting moisture and temperature changes.

- Manufacturing Process: Quality SPC flooring is manufactured with precise control over its composition, which helps to ensure consistent thickness and density. This minimizes the likelihood of the flooring shifting or warping over time.

- Durability and Longevity: Well-made SPC flooring will last longer without expanding or contracting significantly. It can withstand environmental changes better and maintain its appearance and stability even after years of use.

| Quality Aspect | Effect on Expansion and Contraction | Impact on Flooring Performance |

|---|---|---|

| Material Composition | Denser, more stable core | Better resistance to environmental changes |

| Manufacturing Process | Precise control of thickness and density | Longer-lasting and more consistent performance |

| Durability | High resistance to moisture and temperature changes | Reduces likelihood of visible expansion |

5. How Can Proper Installation Prevent Expansion and Contraction Issues in SPC Flooring?

Proper installation is essential to ensuring that SPC flooring performs optimally and doesn’t suffer from expansion or contraction issues.

Correct installation practices, such as acclimating the flooring, leaving expansion gaps, and ensuring a dry, level subfloor, can prevent expansion and contraction problems in SPC flooring.

- Acclimation: Before installation, it’s crucial to allow the SPC flooring to acclimate to the room’s temperature and humidity. This helps the material adjust and reduces the risk of expansion or contraction after installation.

- Expansion Gaps: During installation, leaving an expansion gap around the edges of the flooring is crucial. This gap allows the flooring to expand and contract naturally without causing buckling or warping.

- Subfloor Preparation: Ensure the subfloor is clean, dry, and level before installation. Any imperfections in the subfloor can cause uneven movement in the flooring, leading to gaps or other issues.

| Installation Step | Action | Purpose |

|---|---|---|

| Acclimation | Let the flooring adjust to room conditions for 24–48 hours | Prevents post-installation expansion or contraction |

| Expansion Gaps | Leave appropriate gaps around the perimeter | Allows the flooring to expand and contract freely |

| Subfloor Preparation | Ensure the subfloor is dry, level, and clean | Ensures proper adhesion and stability |

6. Are There Specific Types of SPC Flooring That Are More Resistant to Expansion?

Not all SPC flooring products are created equal. Some types are more resistant to expansion or contraction due to their composition, thickness, and manufacturing process.

Thicker SPC flooring with a denser stone composite core tends to be more resistant to expansion and contraction, making it ideal for environments with fluctuating temperatures and humidity levels.

- Thicker Flooring: Thicker SPC flooring offers more stability and is less prone to expanding or contracting. It’s also more durable and can better withstand the wear and tear of daily use.

- Multi-Layer Construction: Some SPC flooring products feature multi-layer construction, which enhances their resistance to environmental changes. These layers provide added structural integrity, making the flooring less likely to warp or move.

- High-Density Core: SPC flooring with a high-density core offers superior resistance to moisture absorption and thermal changes, ensuring the flooring remains stable in varying conditions.

| SPC Flooring Type | Feature | Benefit |

|---|---|---|

| Thicker SPC Flooring | Higher thickness and more durable core | More resistant to expansion and contraction |

| Multi-Layer SPC | Additional layers for enhanced stability | Better resistance to environmental changes |

| High-Density SPC Core | Denser core material | Increased resistance to moisture and temperature fluctuations |

7. How to Manage and Maintain SPC Flooring to Minimize Expansion Problems?

Proper care and maintenance can help minimize the risk of expansion or contraction issues in SPC flooring.

Regular maintenance, including cleaning, climate control, and periodic inspection, can help ensure that your SPC flooring stays stable and performs well over time.

- Climate Control: Maintaining a stable indoor climate with consistent temperature and humidity levels helps reduce the risk of expansion and contraction. Using dehumidifiers in damp areas and avoiding extreme temperature fluctuations can help keep the flooring stable.

- Regular Cleaning: Regular cleaning prevents moisture from accumulating and causing damage. Use a damp mop and avoid soaking the flooring, as excessive moisture can lead to expansion.

- Inspection: Periodically check your SPC flooring for any signs of warping or expansion. If you notice any issues, address them promptly to prevent further damage.

| Maintenance Task | Action | Reason |

|---|---|---|

| Climate Control | Keep indoor conditions stable | Prevents expansion or contraction due to environmental changes |

| Regular Cleaning | Mop with a damp cloth, avoid excessive moisture | Prevents moisture-related expansion |

| Inspection | Check for signs of warping or expansion | Early detection prevents further damage |

Conclusion

SPC flooring is one of the most stable and durable flooring options available, but it’s not immune to slight expansion or contraction. By understanding the factors that influence SPC flooring’s behavior and following best installation and maintenance practices, you can ensure that your flooring remains stable and performs well over time.

At Kinwin, we specialize in high-quality SPC flooring solutions tailored to your specific needs. Contact us today for a personalized quote and t